Introduction

The Bohai Shipyard is located in Huludao, Liaoning province (400 43’N, 1210 00’E), and is currently part of the China State Shipbuilding Corporation (CSSC), China’s largest shipbuilding conglomerate. The shipyard was founded in 1954, soon after the formation of the People’s Republic of China (PRC).[1] The yard, initially, was equipped with rudimentary facilities, primarily comprising an inclined slipway and a small number of covered sheds to assist in the fabrication process. These facilities were built at the western end of the yard, close to its entrance.[2] To its north and east were low-lying hills, which provided some protection against inclement weather (see Figure 1). While initially tasked with building commercial ships to meet China’s domestic needs, at a relatively early stage it was decided that China’s fledgling nuclear submarine programme would be executed by this shipyard.

Figure 1: The Bohai Shipyard Prior to the Eastern Reclamation

Source: Google Earth, 12 February 2003. (All images in this article are from Google Earth Pro. Analysis pertaining to size and area has been done using tools available in Google Earth Pro.)

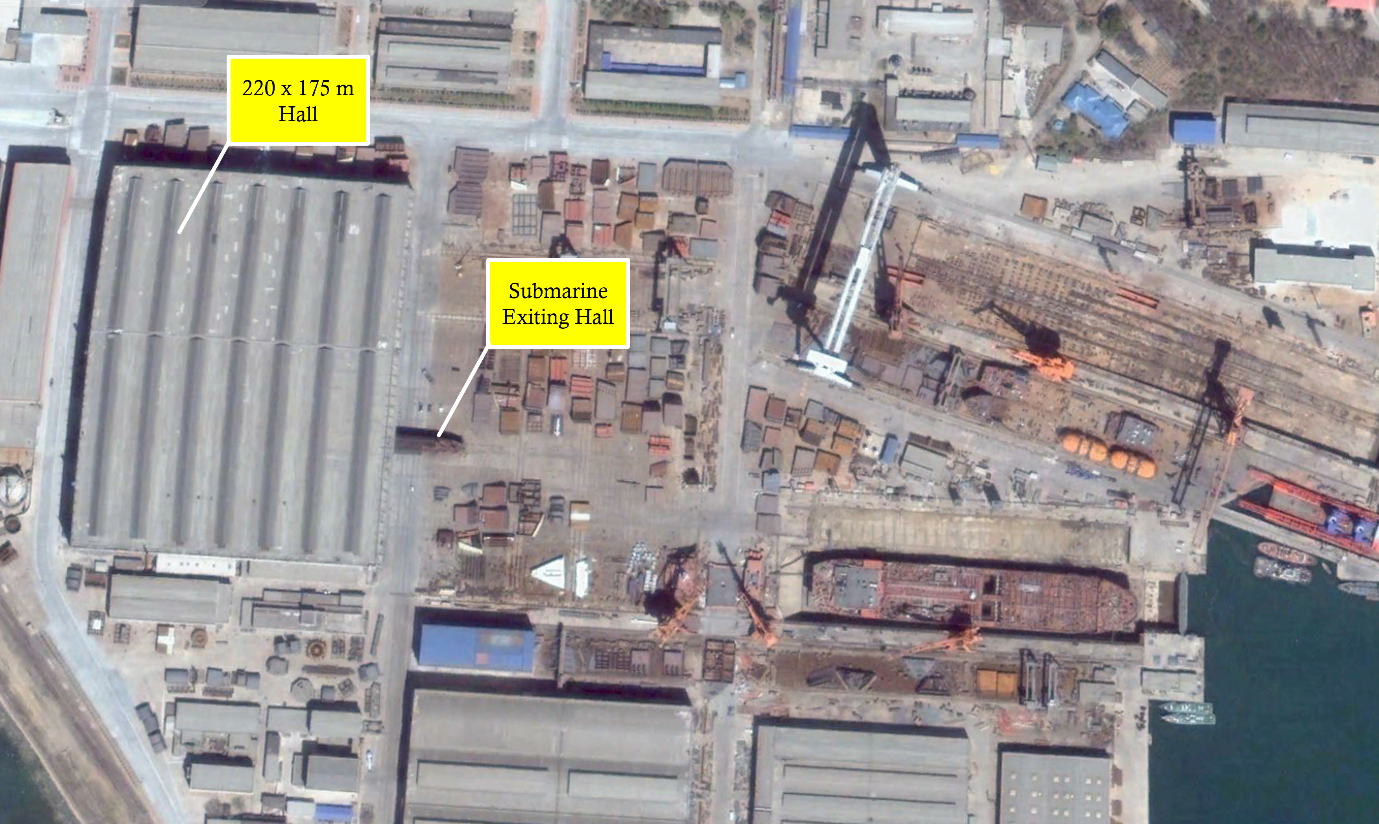

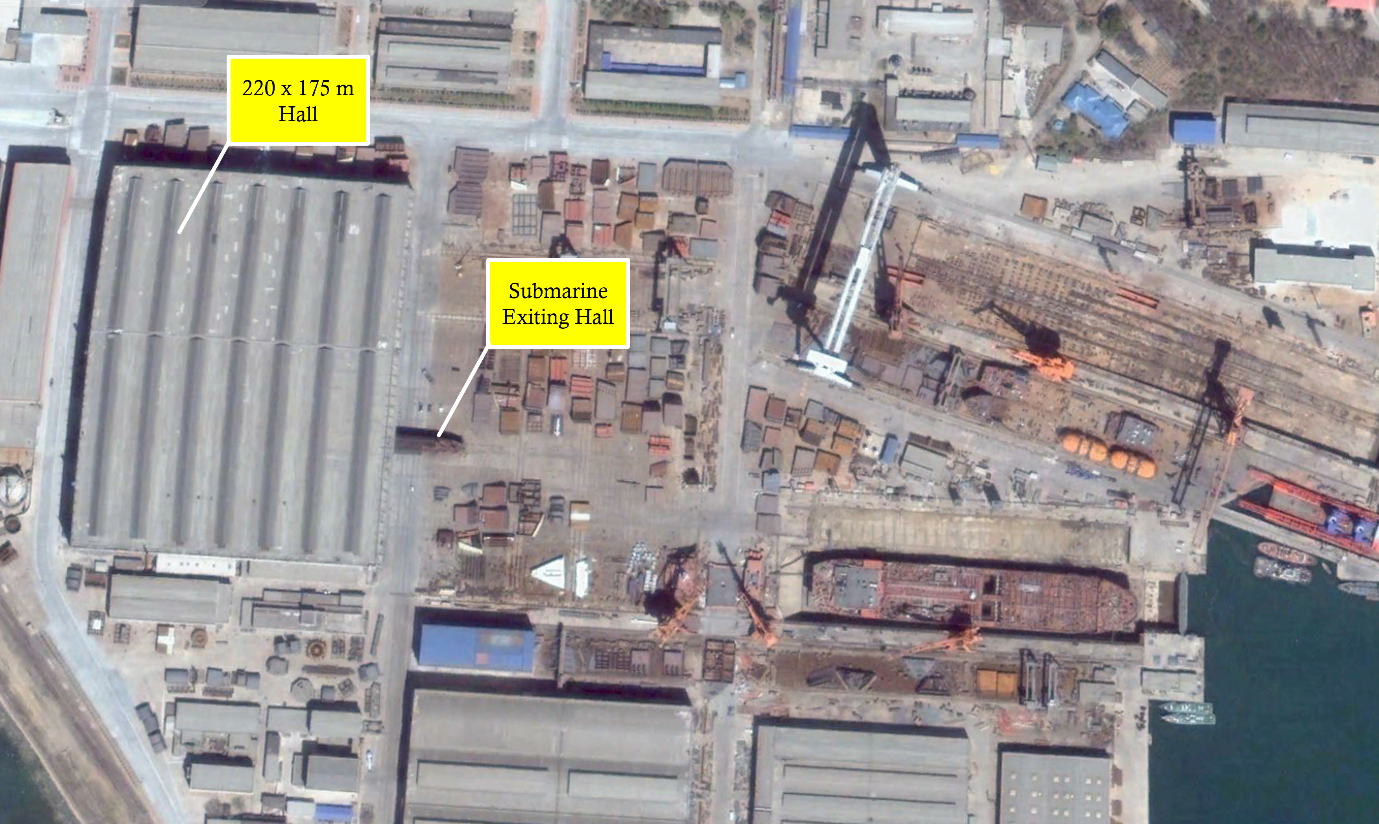

In the 1960s, the shipyard underwent significant infrastructural augmentation (Figure 2), including the construction of a large covered hall (175m x 220m) divided into two sections: the southern part that accommodates four submarine building bays, each 175m long and 30m wide, and the northern part with three similar sections, possibly used for the fabrication of modules. The shed has several (possibly seven) large doors on the eastern side, which can be rolled open for the entry and exit of modules and sections or completed submarine hulls. Just ahead of the covered facility is a large concrete ship-transfer area used for shifting hulls either longitudinally or laterally.

Figure 2: Construction Hall and Transfer Area at the Western End

Source: Google Earth, 3 May 2007

At this time, China also built a drydock 225m long and 40m wide (Figure 3).[3] Abutting the dock on its north is a shallow dock that is just deep enough to accommodate a large pontoon, the top surface of which becomes flush with ship transfer area when the pontoon rests on the base of the shallow dock. This allows vessels to be seamlessly rolled onto the pontoon from the transfer area, from where their launch requires a series of intermediate steps. Once the deeper drydock is flooded, the pontoon with the ship or submarine on its upper surface floats, after which the vessel is moved laterally to the deeper drydock. The pontoon with the vessel on top is then docked on the floor of the drydock, and the buoyancy tanks inside the pontoon are flooded. As a result, when the dock is flooded again, the pontoon remains at the bottom while the vessel floats clear. The vessel is then taken to a fitting out wharf for subsequent work while afloat. For nuclear submarines, a 310m long wharf was built, which is capable of berthing up to three submarines simultaneously.

Figure 3: Drydock and Outfitting Wharf

Source: Google Earth, 15 August 2019

This methodology of launch was adopted at a time when the modern-day synchro-lift had not yet been perfected. The alternative would have been an inclined construction on a slipway, as was being done at the time for conventional submarines in Wuhan, or to build the submarine in the graving dock itself. The drawback of such an approach is that it is not supportive of simultaneous construction; once the keel is laid or sections of the vessel are placed on chalks on the dock floor (if adopting a modular construction), similar activities for follow-on submarines can only commence after the slipway/drydock has been vacated. This slows down the overall pace of construction. While the pontoon method of launch is robust and simple and does not require complex winches coupled with elaborate hoisting mechanisms, it is more time consuming and occupies more space. However, China seemingly found this approach to be practical as it adopted similar methods of launching vessels in the Jiangnan Changxing yard at Shanghai as well as in the eastern extension of Bohai, both of which were built several decades later.[4]

Early Projects

Notwithstanding the turmoil created by the Great Proletarian Cultural Revolution (GPCR), nuclear submarine construction commenced at the yard in the mid-1960s, with the keel of the first Type 09I Han-class attack submarine (pennant number 401) being laid in 1968 and commissioned in 1974. Four more submarines followed, the last of which entered service in 1990.[5] In 1978, the construction of a ballistic missile nuclear submarine (SSBN) commenced at the shipyard; the Type 09II Xia-class was launched in 1981 and commissioned in 1983.[6]

Each of these initial classes of submarines was followed by follow-on projects, with the Type 09III and 09IIIA Shang-class being the newer variants of attack submarines and the 09IV and 094IVA Jin-class being the newer variants of the SSBN. It is estimated that seven to eight Shang-class SSNs and six to seven Jin-class SSBNs were built at this facility.[7] Discounting the slower construction rate of the Han and Xia classes in the formative years of nuclear submarine construction for China, the facilities at the west of the shipyard have been able to construct submarines at the rate of roughly one every 15 months.[8]

Augmentation of Facilities (2003-‘07)

Between 2003 and 2007, while these projects were being executed, the shipyard continued to develop, with a large outfitting wharf added to the northern side and two large drydocks—one 480m long and 110m wide and the other 370m long and 72m wide—constructed on the eastern side (Figure 4). The shipyard then ramped up the construction of commercial ships, with a focus on bulk carriers and offshore platforms. These activities continue till date; the concurrent construction of naval and commercial ships is characteristic of Chinese shipyards involved in military programmes.[9]

Figure 4: Newly Constructed Outfitting Wharf and Drydocks for Commercial Use

Source: Google Earth, 25 October 2013

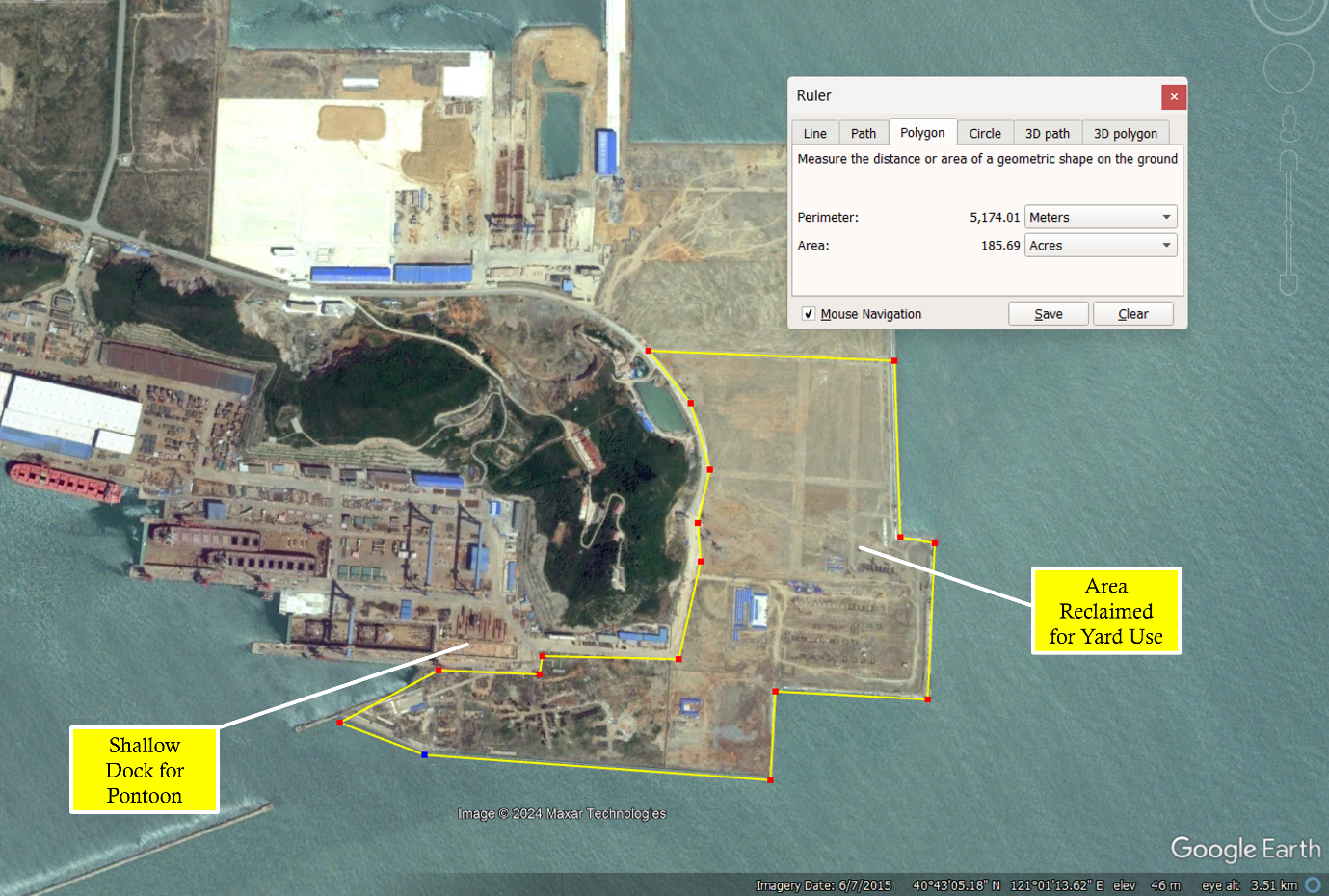

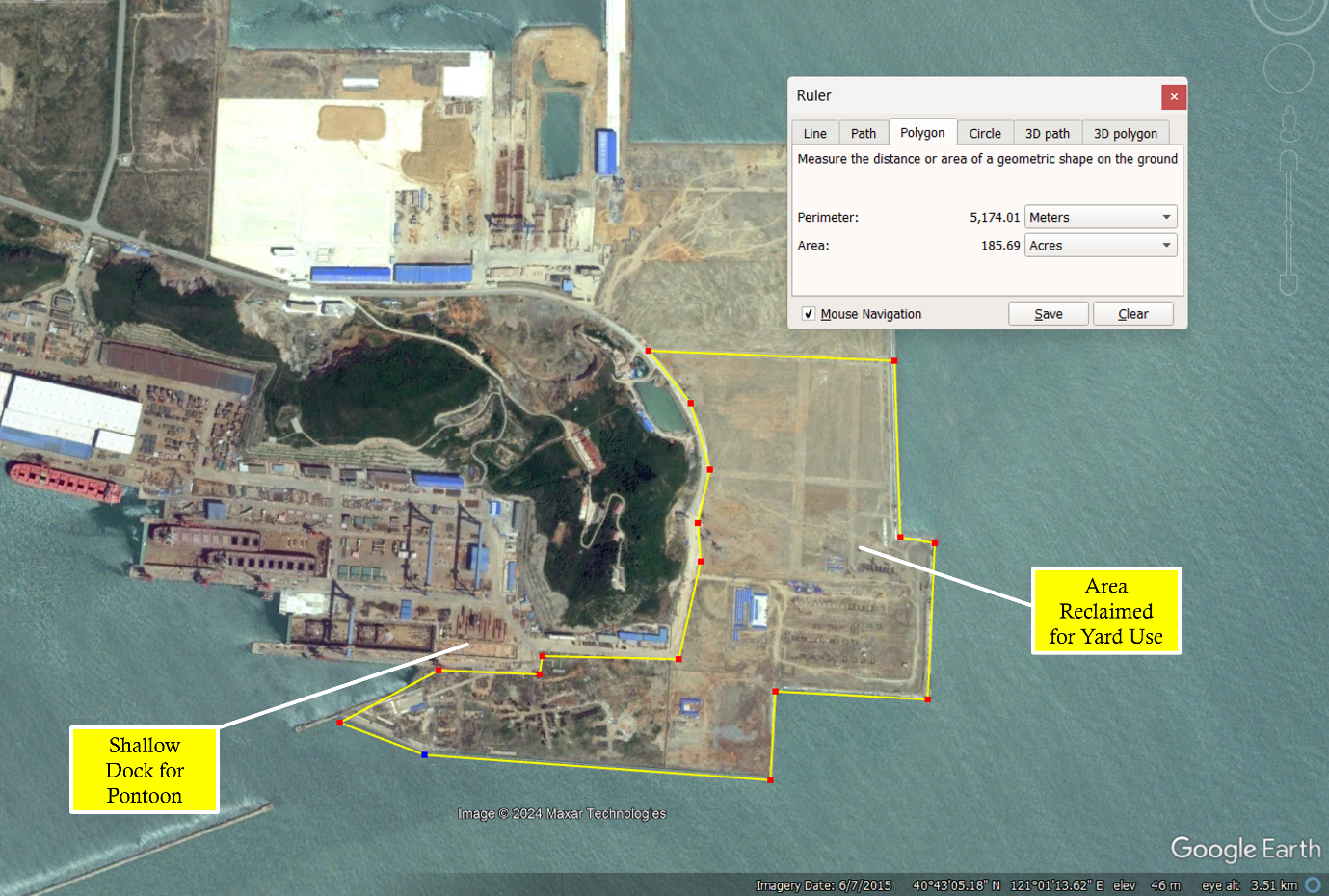

Eastern Reclamation

In 2008, a large reclamation project was initiated on the eastern side of the shipyard (Figure 5).[10] The project was executed in several phases and concluded in 2015 and resulted in the area of the yard increasing by 185 acres to a total of 1,320 acres. The concurrent construction of new facilities was also carried out between 2008 and 2010, including a shallow dock (215m x 35m) abutting the newly built, smaller drydock. This was likely the first indication that the new facilities would be used for submarine building.

Figure 5: Reclaimed Area at the Eastern End

Source: Google Earth, 7 June 2015

Facilities on Eastern Reclamation

The construction of submarine-building facilities commenced on the reclaimed land in 2015. The first phase, completed in 2019, facilitated SSN construction. Several sheds and buildings were commissioned during this phase (see Figure 6).

Figure 6: New Facilities Created in the First Phase, After Reclamation

Source: Google Earth, 11 December 2019

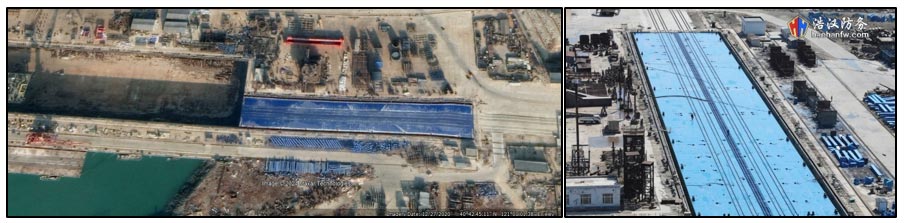

Small Module Fabrication Shed (SMFS)

This structure (205m x 150m; area 27,750 sqm) is divided into five sub-sections; the four western ones are of equal dimensions (28m wide each), while the easternmost section is wider (38m) and taller (see Figure 7). At its northern end, the structure is connected to another shed (170m x 54m; area 9,180 sqm). Components for smaller modules are likely fabricated in the four western sub-sections and the northern shed. These components are then assembled in the larger eastern sub-section, from where they are then taken either directly to the final assembly hall on road transporters or to the southern hall for a merger with larger modules. The facility has large doors to its east and south to facilitate the exit of modules.

Figure 7: The Small Module Fabrication Shed

Source: Google Earth, 16 October 2022

Large Module Fabrication Shed (LMFS)

This structure (185m x 170m; area 31,450 sqm) is also divided into five sub-sections (Figure 8). Moving from east to west, the first two sub-sections are each 23m in width, the next two 32m in width, and the westernmost is 42m in width. Along with an increase in width, there is a commensurate increase in the height of the sub-sections. Given its proximity to the final assembly hall, it is presumed that this shed is used for the assembly of large sections that are subsequently shifted using a road transporter. As the reactor-fuelling facility is located to its immediate west, it may be inferred that this section is also used for the aggregation of the nuclear power plant. There are large doors to the west and south—the former to facilitate access to the fuelling facility and the latter for shifting fabricated sections to the FAH.

Figure 8: The Large Module Fabrication Shed

Source: Google Earth, 16 October 2022

Reactor Fuelling Facility (RFF)

This structure is located to the immediate east of the LMFS. While the original building measures 56m x 44m, a structure (34m x 30m) was constructed to its immediate west in 2021-22. The double-walled containment of the original building was evident in images while it was still under construction (Figure 9A). Therefore, it is likely that the building is used for handling reactor fuel. There are two large doors on the western side, each with its own set of rails (Figure 9B), likely for transporting fuelled reactors to the LMFS. The new addition to the east is presumably for capacity expansion.

Figures 9A and 9B: Reactor-Fuelling Facility Under Construction; Completed

Source: Google Earth, 19 October 2017; Google Earth, 27 December 2022

Final Assembly Hall (FAH)

This is a large building (288m x 135m wide; area 38,880 sqm), divided into three sub-sections, each 45m wide (Figure 10). Each sub-section has its own set of gantry cranes and accommodates four building bays for submarines—two to the west and two to the east, thereby amounting to a total of 12 building bays in the building. There are large doors on the western side of the FAH (two per sub-section) to receive modules from the SMAS and LMAS. Once the final assembly is completed, the submarine is rolled out to the Submarine Transfer Area (STA) using cradles that travel on twin rails, the outer of which are approximately 7.5m apart.

Figure 10: Final Assembly Hall

Source: Google Earth, 27 December 2022

Submarine Transfer Area (STA)

The STA is a large concrete platform with rails that permits both the longitudinal and lateral movement of submarines that are fabricated in the FAS (Fig 11). It is primarily used for shifting submarines from the FAS to the Painting-cum-Tiling Shed (PTS) and from there to the launching pontoon.

Figure 11: Submarine Transfer Area

Source: Google Earth, 27 December 2022

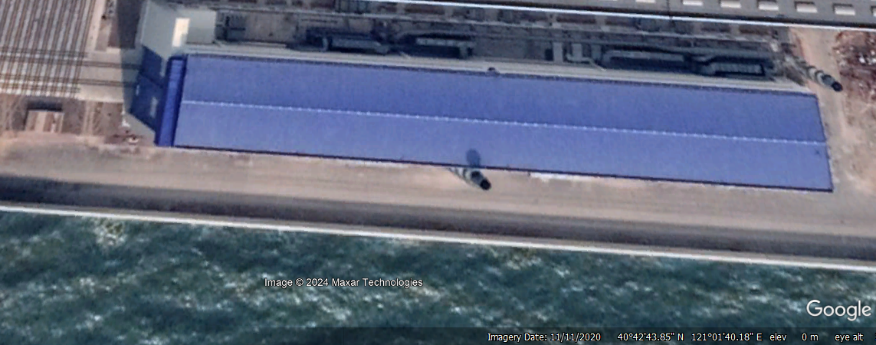

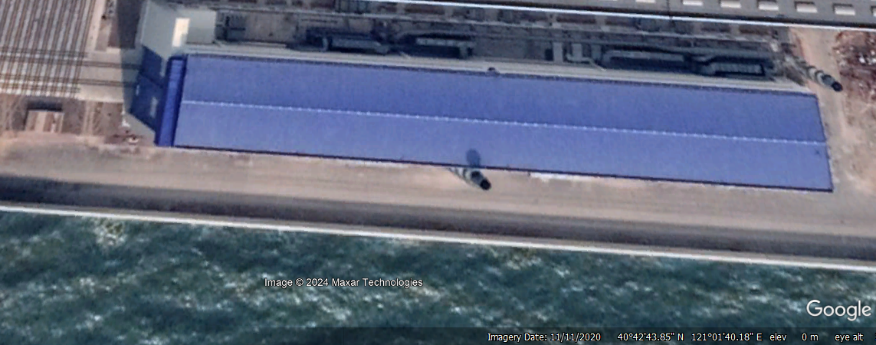

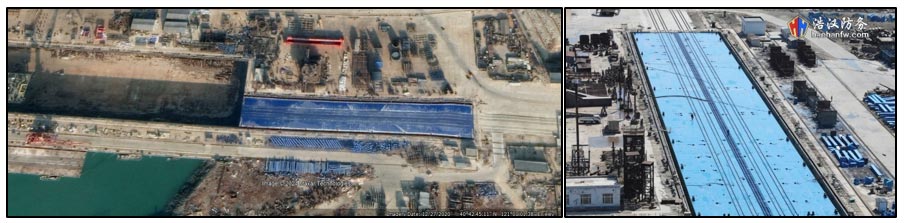

Painting-cum-Tiling Shed (PTS)

This is a building (194m x 30m) to the immediate south of the FAS (Figure 12). It is assessed that submarines from the FAS are shifted to this building for painting as well as for the fitment of anechoic tiles for acoustic silencing.

Figure 12: Painting-cum-Tiling Shed

Source: Google Earth, 11 November 2020

Shallow Dock for Pontoon (SDP)

After the painting and tiling have been completed, the submarine (on its cradle) is rolled over a distance of about 900m onto a pontoon docked in the shallow dock abutting the smaller drydock (Figure 13A). When docked, the upper surface of the pontoon is flush with the STA, with the rails perfectly aligned, thereby allowing the cradle (with the submarine) to smoothly traverse onto it (Figure 13B). Given the long distance of this transit, an additional set of outer rails has been provided to allow for greater stability in movement. From here, the procedure for launch is similar to that described while examining the older facilities at the western end of the yard. Once launched, the submarine is taken to the fitting out wharf for further outfitting prior to the commencement of trials.

Figure 13A and 13B: Pontoon Positioned in Shallow Dock; Rails Perfectly Aligned

Source: Google Earth, 27 December 2020

The construction of another Final Assembly Hall, along with its own Submarine Transfer Area, at the southern end of the reclaimed area began in 2019 and was completed in 2021 (Figure 14).

Figure 14: New Final Assembly Hall, Presumably for SSBN Construction

Source: Google Earth, 27 December 2022

New Final Assembly Hall (NFAH)

This structure (315m x 130m; area 40,950 sqm) is divided into two sub-sections, each 65m wide. Each sub-section has four submarine building bays, resulting in a total of eight at this hall. Given the increased size of each bay (157.5m x 144m), it could be inferred that this facility is used for the final assembly of SSBNs while the earlier constructed FAH is used for SSNs. Another point of differentiation between the two FAHs is that, in the NFAH, each sub-section is fitted with three doors at its western end compared to two in the FAH to allow large modules to be taken to the rear building bays on wheeled transporters, even if the forward bays are occupied, thereby increasing efficiency. There is a Submarine Transfer Area in front of the NFAH to cater to the movement of submarines from the building bays to the PTS for launch. As there are no separate facilities for the construction of modules at this location, it could be inferred that existing facilities such as the SMFS, LMFS, and RFF will support the NFAH. In addition to the buildings described above, there are several facilities at the yard whose exact purpose is difficult to ascertain.

It may thus be seen that the four submarine building bays at the western end of the yard have now been augmented by 20 bays in the newly reclaimed area. These are supported by an increasing number of facilities for the construction of ancillaries, sub-modules, modules, and nuclear power plants. There are also several new support buildings under construction (Figure 15).

Figure 15: Additional Facilities Under Construction

Source: Planet, 19 July 2024, with annotations by AllSource Analysis[11]

Assessing the Nuclear Submarine Build Capacity of the Shipyard

How do the submarine facilities and Bohai shipyard compare with other established nuclear submarine building yards? An examination of the images of these facilities is revealing (Table 1).

Table 1: Select Nuclear Submarine Building Shipyards[a]

| Name and Location of Facility |

Area of FAH |

Estimated Number of Submarine Building Bays |

Assessed Rate of Construction (Subs Per Year) |

| Electric Boat, Groton, US |

148 x 76 m (11,248 sq m) |

2 |

0.7 |

| Newport News, US |

190 x 92 m (17,480 sq m) |

3 |

0.7 |

| Sevmash, Russia |

435 x 120 m (52,200 sq m) |

9 |

2 to 3 |

| Barrow-n-Furnace, UK |

270 x 65 m (17,550 sq m) |

4 |

0.3 |

| Bohai Shipyard, Huludao (Old Facility) |

175 x 220 m (38,500 sq m) |

4 |

0.8 |

| Bohai Shipyard, Huludao (New Facility) |

1. 288 x 135 m 2. 315 x 130 m (79,830 sq m) |

20 |

|

As seen in Table 1, the Bohai shipyard is the largest submarine building yard globally. The old and new facilities together have 24 submarine building bays located in three FAHs, covering a total area of 118,330 sqm. While locating all nuclear submarine capability in one yard does create a single point vulnerability, it also increases efficiency. In any event, with the exception of the United States (US), which has two nuclear submarine building shipyards, all countries concentrate these capabilities in a single location. Even in the case of the US, the two yards function as a single entity, with all the bow and stern sections of Virginia-class submarines being made by HII’s Newport News Shipbuilding and the mid-sections (including the nuclear power plant) being made by Electric Boat.[12]

With the new facilities for SSNs and SSBNs being completed at Bohai, one could assume that all construction activity would shift to the eastern side of the yard, with the older facilities possibly being utilised for repairs and refits. This becomes all the more probable as with the increasing number of nuclear assets, existing repair facilities at the First Submarine Base at Jianggezhuang and the Second Submarine Base at Yalong Bay, Hainan may not be sufficient to meet the load.

It is apparent that SSN production has been underway at the newly created facility for a few years, with the first boat having been launched in May 2022.[13] According to open sources, as of July 2023, six SSNs (all fitted with Vertical Launch Modules for missiles) have been launched and are currently undergoing either outfitting or sea trials.[14] The launch dates are tabulated in Table 2.

Table 2: Launch Dates of SSNs from the New Facility of Bohai Shipyard

| |

Launch Month |

Interval Between Launches (in Months) |

|

May 2022 |

|

|

January 2023 |

7.5 |

|

July 2023 |

5.5 |

|

October 2023 |

3.5 |

|

February/March 2023 |

4 |

|

July 2023 |

4 |

From Table 2, it is evident that after initial inconsistencies, the SSN construction rate appears to have stabilised, with one boat being launched every four months, which amounts to three submarines per year. It is likely that with increasing experience and newer support facilities, this number may rise to an assessed maximum of four per year. Insofar as SSBNs are concerned, if this construction drumbeat is extrapolated to the NFAH, which has eight building bays (against 12 for SSNs), the expected build rate would be 2-2.67 submarines per year. However, given the increased complexity of these platforms, a pared down build rate of 1.5-2 per year is more likely. The overall assessed construction rate of the yard is tabulated in Table 3.

Table 3: Overall Nuclear Submarine Build Capacity of the Bohai Shipyard

| Type |

Number per year |

| SSN |

3 to 4 |

| SSBN |

1.5 to 2 |

| Total |

4.5 to 6 |

While these numbers may appear to be inordinately large, they are consistent with the scale and size of the facilities created, even when compared to the build rate of other nuclear submarine shipyards. Further, for a nation to be able to resource such a high rate of construction is not unprecedented. Throughout the Cold War, both the US and the Soviet Union had several shipyards that were engaged in nuclear submarine construction and were, on average, building a total of four to six boats a year. What is unique in the Chinese case is the concentration of all such activity at a single shipyard.

It appears that nuclear submarines have crossed a Rubicon similar to the Destroyers—where, after several rounds of iterative improvements over numerous classes built in small numbers, the rapid induction of 25 Type 52D (Luyang III) vessels, followed by ten more, signaled design maturity. It is evident that China’s nuclear submarine construction moment has arrived.

Rear Admiral Monty Khanna (Retired) is a submariner who retired from the Indian Navy in 2019 after 37 years of commissioned service.

Endnotes

[a] The number of submarine building bays inside final assembly halls has been assessed based on imagery and published photographs of the interior (where available). An assessment of the rate of construction has been conducted based on published data (where available).

[1] Global Security, “Bohai Shipbuilding Heavy Industry Co., Ltd,” https://www.globalsecurity.org/military/world/china/bohai.htm

[2] Assessment based on an examination of historical imagery on Google Earth Pro. https://www.google.com/intl/en_in/earth/about/versions/#earth-pro

[3] Measured using the Toolbar on Google Earth Pro. https://www.google.com/intl/en_in/earth/about/versions/#earth-pro

[4] Assessment based on an examination of historical imagery on Google Earth Pro. https://www.google.com/intl/en_in/earth/about/versions/#earth-pro

[5] Amit Ray, Tracing the Undersea Dragon: Chinese SSBN Programme and The Indo- Pacific (Routledge India, 2023): 43-44.

[6] Ray, Tracing the Undersea Dragon: Chinese SSBN Programme and The Indo- Pacific.

[7] Ronald O’Rourke, China Naval Modernization: Implications for U.S. Navy Capabilities- Background and Issues for Congress, Congressional Research Service, 2024, https://crsreports.congress.gov/product/pdf/RL/RL33153/; U.S.- China Economic and Security Review Commission, “Hearing on “China’s Pursuit of Defence Technologies: Implications for U.S. and Multilateral Export Control and Investment Screening Regimes,” August 13, 2023, https://www.uscc.gov/sites/default/files/2023-04/Sarah_Kirchberger_Testimony.pdf.

[8] Department of The Navy, Office of Naval Intelligence, “Unclassified Brief,” February 6, 2020, https://irp.fas.org/agency/oni/plan-trends.pdf.

[9] Monty Khanna, “Understanding China’s Naval Ship Building Industry – Lessons India Can Learn,” Maritime Affairs: Journal of the National Maritime Foundation of India 15, no.1, June 25, 2019, https://www.tandfonline.com/doi/pdf/10.1080/09733159.2019.1631512.

[10] Assessment based on an examination of historical imagery on Google Earth Pro. https://www.google.com/intl/en_in/earth/about/versions/#earth-pro

[11] AllSource Analysis (@AllSource Analysis), ”GEOINT analysis of the Huludao (Bohai) Shipyard in China on 19 July 2024, reveals construction of new buildings on site,” LinkedIn post, July 19, 2024, https://www.linkedin.com/posts/allsource-analysis_geoint-china-huludao-activity-7224470399298760704-mP0Y.

[12] Sam Lagrone, ”General Dynamics Electric Boat Launches Attack Boat Idaho,” USNI News, August 13, 2024, https://news.usni.org/2024/08/13/general-dynamics-electric-boat-launches-attack-boat-idaho

[13] Greg Torode, “Satellite images raise prospect of new class of Chinese submarine,” Reuters, May 10, 2022, https://www.reuters.com/world/china/satellite-images-raise-prospect-new-class-chinese-submarine-2022-05-10/

[14] Sino Defence Forum, “09III/09IV (093/094) Nuclear Submarine Thread,” November 22, 2013, https://www.sinodefenceforum.com/t/09iii-09iv-093-094-nuclear-submarine-thread.6883/page-351

The views expressed above belong to the author(s). ORF research and analyses now available on Telegram! Click here to access our curated content — blogs, longforms and interviews.

PDF Download

PDF Download

PREV

PREV