1: Gandhi and Ambedkar

Limited-edition fountain pens are luxury items, much like jewellery. Some of the most expensive fountain pens in the world include Mont Blanc, Caran d’Ache, and Aurora. Many would recall that not too long ago, a controversy erupted over Mont Blanc’s limited-edition “Gandhi pens” and a case was filed before the Kerala High Court. There were two limited editions in fact, one in silver and the other in gold, a ‘Limited Edition 3000’ (i.e., 3,000 of it were manufactured) and a Limited Edition 241 (‘241’ for the 241 miles of the Salt March; 241 pieces of it were made). Both kinds had an image of Mahatma Gandhi on the nib. Mont Blanc’s decision to manufacture these pens provoked massive controversy: to begin with, it violated the Emblems and Names (Prevention of Improper Use) Act of 1950, which restricts use of the name or pictorial representation of Mahatma Gandhi. Equally important, the public did not think it appropriate to link the name of Gandhiji—a universal symbol himself of simple living—with pens that cost several lakhs of rupees. Indeed, some years earlier, there was no comparable controversy when the Aditya Birla group started to sell ‘Eternal Gandhi’ products, including fountain pens. The reason was obvious: Eternal Gandhi fountain pens are not frightfully expensive.

Yet, it is not only because of their price that Mont Blanc’s Gandhi pens were not welcomed by many. Indeed, there is an element of incongruity in linking Gandhiji’s name with fountain pens, whether they are cheap or luxuriously priced. Mahatma Gandhi did not like fountain pens; he preferred reed pens, those in use before the advent of fountain pens. This comes across clearly in his letters. On 20 March 1932, he wrote to Parasram Mehrotra, “There is not the slightest need for the girls to use a fountain pen. Really speaking, nobody in the Ashram should need a fountain pen. Why should anybody be in such hurry? For students at any rate, it is certainly a harmful thing to use. The reed-pen is the best for writing Gujarati, Hindi, Urdu and other Indian scripts.”[1] On 13 May 1932, he wrote to Mirabehn, “It is well if you do without the fountain pen.”[2] On 17 April 1937, he wrote to Amrit Kaur, “If we are to re-introduce village articles after being used to the Western style, we shall have to be patient and inventive. That the pen requires constant dipping is a good point. It lessens fatigue. That the fountain-pen saves time is not an unmixed blessing. The village pen and ink undoubtedly admit of improvement. That can only come when you and I use these things.”[3] In October 1938, he wrote to Lilavati Asar, “And do not follow Mahadev’s example of writing with a fountain-pen. I tolerate Mahadev’s fountain-pen because Mahadev is a scribe. You are not a scribe and are not going to be one. So, I shall not, and I should not tolerate the fountain-pen in your case.”[4] On 28 April 1947, there was his “Advice to Students”:[5] “For example, (1) when you get up in the morning you can roll up your own bedding; (2) help in preparing your breakfast and milk, etc., whatever you take, without waiting for your mother or anyone else to prepare it and serve you; (3) give a helping hand in sweeping and scrubbing; (4) do your own laundering; (5) help your mother with the cooking and cleaning the dishes; (6) make your own cloth by spinning regularly every day; (7) keep your books clean and neatly arranged, economize on exercise books as much as possible; (8) learn to do with a pen-holder and ink costing two annas, instead of a fountain-pen costing Rs. 50.” On 14 July 1947, he wrote a letter to a child:[6] “You should give up your fondness for writing with a pencil or fountain-pen. Anybody who wishes to improve his handwriting should use a reed-pen. How can all the children in the country afford to use fountain-pens? I suppose you know how much a fountain-pen costs. If I was a teacher and had my way, I would forbid the bringing of a fountain-pen into the classroom. But mine has become a lone voice now. If you have any influence with your friends, popularize the use of the reed-pen among them.”

Why was Mahatma Gandhi against the use of fountain pens? That had to do with his ideal of a self-sufficient village economy. In November 1934, he wrote an article on village industries, where he said in part:[7] “In a nutshell, of the things we use, we should restrict our purchases to the articles which villages manufacture. Their manufactures may be crude. We must try to induce them to improve their workmanship, and not dismiss them because foreign articles or even articles produced in cities, that is, big factories, are superior. …If this is the correct attitude, then, naturally, we begin with ourselves and thus use, say, handmade paper instead of mill-made, use village reed, wherever possible, instead of the fountain pen or the penholder, ink made in the villages instead of the big factories, etc. I can multiply instances of this nature. There is hardly anything of daily use in the home which the villagers have not made before and cannot make even now.”

In 1937, Mahadev Desai received a letter sent by Prabhudas Gandhi, where it was written: “Some time back in an article entitled ‘Wanted Rural-mindedness’, you recommended, as a step in that direction, the adoption of the reed-pen in the place of the fountain-pen. I was struck by your argument, and after reading Bapu’s interpretation of the A. I. V. I. A.[8] membership pledge, I laid aside my fountain-pen and took to the reed, nine months back. I was not altogether unused to the reed-pen. . . .After a month of baffling experience, however, I was again forced to return to the fountain-pen a sadder and a wiser man. The reasons which compelled the change were as follows: (1) It took three hours to copy out matter, using a reed-pen, that could be done with the fountain-pen in one hour and a half. . .(2) It took at least from a quarter of an hour to three quarters of an hour to mend one reed-pen by means of an indigenous village knife. . .(3) The fountain-pen enables you to make short jottings and entries, so indispensable in the course of village work, while standing, or while you are on the move. When I reverted to the use of the reed-pen, I invariably found that my diary-writing and maintenance of other daily records and registers fell heavily into arrears…Surely, it is no part of the policy of the A.I.V.I.A. to slave-drive its workers to the very limit of their capacity.”

Gandhiji responded through an essay, titled, ‘The Reed versus the Fountain Pen’ and said: “The village-dweller has not to work under high pressure or to speed about from place to place in motor cars and trams like the city dwellers. All this work is done by the easier and more natural modes of locomotion. Similarly the fountain-pen can have no place in his economy. I might, perhaps, reluctantly go so far as to admit the steel nib as a compromise, but that is all. The steel nib in my opinion has spelt the death of the calligraphist’s art the mending of a reed-pen was itself an art. It called into play the artistic skill and the personality of the scribe that was reflected in the characters which he traced. All that has gone with the advent of the steel pen. But the steel pen has not done even half the mischief that the fountain-pen is doing. The introduction of the fountain-pen in the village, to me, marks the beginning of the end of the existence of the village as such and its slow metamorphosis into the city.”[9] This figured again in a discussion with Maurice Frydman in January 1939:[10] “Again, I dislike fountain-pens, but just now I am making use of one though I carry a reed pen about in my box. Every time I use the fountain-pen it hurts me and I think of the neglected reed pen in my box. Compromise comes in at every step, but one must realize that it is a compromise and keep the final goal constantly in front of the mind’s eye.”

It was not entirely about the self-sufficient village economy though; there was a touch of swadeshi as well. Pens, fountain pens or reed pens, require ink. On 15 December 1932, Gandhiji wrote to Jamnalal Bajaj, “Shri Kateli knew that we had a stock of the swadeshi ink for fountain pen which you wanted, and, therefore, we have sent a bottle of it for you. We have quite a large quantity of it.”[11] In 1947, when advising students, he talked about fountain pens priced at Rs 50. While we do not have official price indices that go as far back as 1947, roughly in today’s prices, Gandhiji was talking about fountain pens with price tags of around Rs 15,000. These were imported pens and they were expensive. Therefore, they were valuable enough to be donated. Thus, fountain pens figure in the 1934 notes on Bihar.[12] “At these meetings women have given their bracelets and men their rings, young students their fountain pens because they had nothing else to give.” In 1937, when Gandhiji asked for donations for the Harijan Institute, The Hindu newspaper reported: “Small cash, jewels, watches and fountain pens were offered.”[13]

But Gandhiji did possess at least one fountain pen. On 16 July 1935, he wrote a letter to K.V. Ratnam of Ratnam Fountain Pen Works, Rajahmundry.[14] The letter said in part, “Dear Ratnam, I must thank you for the fountain pen you have sent me through Shri Kumarappa. I have received it and it seems to be a good substitute for the foreign pens one sees in the bazaars.” In 1921, Kosuri Venkata Ratnam met Gandhiji in Wardhwa.[15] He was from a family of goldsmiths and he presented Gandhiji with some art work. He suggested they should manufacture products that were not too expensive and could be used by Indians. Venkata Ratnam and his brother, Satyanarayana, turned to fountain pens and set up Ratnam Pen Works in 1932.[16] The first pen, manufactured in 1932, went to Nyapathi Subba Rao Pantulu. Born in 1856, Nyapathi Subba Rao Pantulu might not have made much use of the first fountain pen produced in India. The second pen, made of ebonite, was sent to Mahatma Gandhi, probably in 1932, though the year might also have been 1933. Since it was not swadeshi enough, Gandhiji rejected it and in 1935, a second pen was sent to him through J.C. Kumarappa, then Secretary of A.I.V.I.A. This pen was the subject of the 1935 letter.

One of Gandhiji’s pens was stolen, though there is nothing to indicate this was the Ratnam pen. It probably was not, since the stolen pen was an expensive one. “Most people have lost a pen at some time or the other. So did Gandhi. He had a costly fountain pen which was pilfered. The pen was immediately replaced but the theft pained him. Henceforth, he decided, he would not use anything so attractive that it would tempt someone to steal it.

He began using a pen-holder and a nib.”[17] Mirabehn also referred to the incident of the fountain pen being stolen: “It is not a fountain pen which he is using; some misfortune happened to his last one, since when he writes with an ordinary nib and holder. The ink-pot is one of Bapu’s little patents, and consists of a tiny balm bottle fixed in a wooden stand which also carries pen and pencils. The little old tin screw top of the balm bottle Bapu most delicately puts off and on every time he uses his ‘ink-stand’.”[18] Occasionally, Mahatma Gandhi still used fountain pens. There are photographs of him doing so. For instance, there is a 1940 photograph of Gandhiji taken by Kanu Gandhi, which has been reproduced quite often since then. In it Gandhiji is sitting, writing with a fountain pen. In 2018, a rare signed photograph of Gandhiji was auctioned, depicting Gandhiji walking with Madan Mohan Malaviya, at the time of the Round Table Conference in 1931. This rare photograph was signed by Mahatma Gandhi, with a fountain pen.

On 24 September 1932 the Poona Pact was signed and Dr Rajendra Prasad, Babasaheb Ambedkar and C. Rajagopalachari were signatories. We are told, “While signing the pact, Rajagopalachari was so much overjoyed that he exchanged his fountain-pen with Dr. Ambedkar.”[19] It would have been quite something had Ambedkar exchanged his pen with Mahatma Gandhi’s pen. Babasaheb Ambedkar was fond of fountain pens, not reed pens. “Apart from books, he had an insatiable desire to possess fountain pens and outsize ones at that! No ordinary ones would do, and John, who attended to his pen and stationery needs, used always to scamper and collect all the outsize pens available in town and offer than to him, one by one. The Doctor would lean heavily against a show-case and try pen after pen on a writing pad, scrawling his broad sprawling autograph on its pages. At the end of these trials, he would grab half a dozen pens that he fancied and thrust them into this capacious coat pocket! It was during one such ‘pen-trial’, sometime in July 1946, that I was with him in Thacker’s shop…”[20] Babasaheb Ambedkar was especially fond of Parker, Sheaffer and Waterman. In Bombay (now Mumbai), his fountain pens (and other stationery) came from Thacker and Company. In Delhi, they came from Dhomimal Dharamdas, now transformed into Dhoomimal Art Gallery. Portraits, pictures and statues of Babasaheb Ambedkar often show him with a fountain pen in his hand or pocket, a symbol of modernity; Gandhiji, meanwhile, is depicted with his reed pen. One might say that the exchange of the reed pen for the fountain pen is illustrative of India’s economic transition.

2: Imports and Swadeshi

In 1911, a remarkable gentleman authored a remarkable book:[21] Dr R. N. Saha, a medical doctor and Member of the College of Physicians and Surgeons (MCPS). He was also an inventor. Among several other things, he invented a “tubular feed fountain pen” and set up the Luxmy Stylo Pen Works in Varanasi. Dr Saha’s book tells us that the first mention of a fountain pen is found in Hutton’s Mathematical Dictionary (published in 1795).[22] The dictionary has a quaint definition of a fountain pen: “The fountain-pen consists of divers pieces of metal, the middle piece carrying the pen, which is screwed into the inside of a small pipe; and this again is soldered into another pipe of the same size as the lid; in which lid is soldered a male screw, for screwing on the cover; as also for stopping a little hole at the place, and hindering the ink from passing through it: at the other end of the piece is a small pipe, on the outside of which may be screwed the top cover. A portecraion (sic) goes in the cover, to be screwed into the last-mentioned pipe, to stop the end of the pipe into which the ink is to be poured through a funnel. To use the pen, the cover must be taken off, and the pen a little shaken, to make the ink run more freely.” Except that last sentence, which makes sense even today, everything else sounds awfully complicated. Shorn of complications, though, a fountain pen is simply a pen with an in-built reservoir of ink, so that you do not have to constantly dip into ink-pots.

In 1911, Dr Saha gave us a list of 120 patents granted on different types of fountain pens. This was obviously an area in which a lot of innovation was occurring. Dr Saha himself obtained patents on a stylo-pen – in India, Britain, Germany and the United States. That is how Luxmy Stylo Pen Works was set up in Varanasi in 1907. “It manufactures pen surpassed by no other pen in quality and durability, and their price is much cheaper than that of any imported pens.” The company also produced fountain pens. Thus Saha, rather than Ratnam, should probably claim that record. In passing, the book mentions nib factories that had been started in India – Gwalior State Nib Factory, a factory set up in Mumbai by Tambat Brothers, and the Gujarat Nib Factory in Punjab. There is also a list of 14 global fountain pen makers in 1911: (1) Mabie, Todd and Bard (London), with the “Swan” brand; (2) Waterman (New York); (3) De La Rue (London and USA), with the “Nota Bene”, “Pelican”, “Onoto” and “Onostyle” brands; (4) Jewel Pen Company (London); (5) Eagle Pencil (New York); (6) Moore’s; (7) Dr Faber (Toledo); (8) A. W. Faber (USA), with the “Independent” brand; (9) Burge, Warren and Ridgley (London); (10) Parker and Lawrence; (12) A. T. Cross (England and USA); (13) Paul Ewart Bloomsbury (USA); and (14) Conklin Pen Company (Toledo, USA). Coincidentally, 1911 was the year when a sailor friend gave Kyugoro Sakata, an engineer based in Hiroshima, a fountain pen imported from England. This led to the establishment of Sailor Pens, the first company to make fountain pens in Japan.

Notwithstanding R. N. Saha, the initial fountain pens were imported—the most popular brands were Parker, Sheaffer, Waterman, Swan, Blackbird and Pilot. Importers often turned to making pens. There was Rajahmundry, Andhra Pradesh, with Ratnam, Ratnamson and Guider, though Guider pens started much later, in 1946. Guider was “guided” by Ratnam. “This eminent pen company was started under the guidance of experienced persons named ratnam & brothers in the year 1946, situated in rajahmundry bank of the river godavari in andhra pradesh. In the olden days they used to manufacturing manually due to insufficient power supply. the raw material was also imported from japan. still the company is having the raw material and pens which made by the professionals above 50 years back. you can choose gold nibbed pens, silver body engraved art pens, celluloid, ebonite, acrylic pens, ball pens & marble stone pens.”[23]

Indeed, there was something special about undivided Andhra Pradesh. Other than Ratnam, Ratnamson and Guider, there was Deccan Pen Stores in Hyderabad. At that time, Hyderabad was a prosperous area, with a lot of commerce and trade. In addition, University of Osmania was established in 1918, bringing teachers and students, and the need for writing instruments. A farmer from Allahabad, S. A. Siddiqui, detected a business opportunity. He first bought pens from Calcutta and started to sell them in Hyderabad, initially going door-to-door and then eventually through Deccan Pen Stores, which he established in 1918. He then got dealerships from foreign pen manufacturers. But pens that had been sold would have to be repaired and customers came back to get their pens repaired. That led to Deccan Pen Stores actually making fountain pens and selling them under its own brand name. Several years down the line, the pattern was no different for Hilal Pen Stores, also in Hyderabad. Abdul Razzaq originally hailed from Kashmir and eventually joined the Nizam of Hyderabad’s army. After retirement, he set up a pen shop, which became a much larger pen shop in 1932. But this still meant importing fountain pens and selling them, until Hilal Pen Stores started making its Sultan brand of pens in 1952.

Before Independence, there were other parts of India where this pattern replicated itself. In the 1920s, Gem and Company was set up in Chennai by S. Venkat Rangam Chetty and M. C. Cunnan. The brand, which still exists, is known as Gama. The allusion is to Ghulam Mohammad Baksh Butt (1878-1960), known as the Great Gama, the world wrestling champion, who was at the height of his fame in the 1920s. Before this brand was established, Gem and Company used to import Parker and Waterman and sell them in India. It was therefore remarkable that the first Gama pens should have been designed in Madras and made in England. In the early 1950s, Gem and Company featured in the celebrated Alavandar murder case. The murdered salesman, Alavandar, used to work for Gem and Company and enticed young women by offering them gifts of fountain pens, which were a precious commodity at the time.[24]

Osmania University was established in 1918 and Banaras Hindu University (BHU) was established earlier, in 1916. If Osmania University triggered a demand for writing instruments, why did BHU not have a similar effect? Tara Prasad Sahu switched from selling fodder to selling fountain pens near the BHU campus. In 1946, this became Penco, which is also a bit of a pen museum. Penco not only dealt with foreign brands, it eventually started to sell its own brands. In distant Thrissur, though not a maker of fountain pens, there was Honest Pen Hospital, established in 1937 by Kaalathodu Koluthu Parambil Abdulla. Both Kaalathodu Koluthu Parambil Abdulla and S. A. Siddiqui learnt the skills of repairing pens from Calcutta. As the then capital of British India, it was but natural that there should be several agents in Calcutta who imported foreign pens. It was also natural that these pen-users would wish to get their pens repaired. Several pen hospitals sprouted all over Calcutta and one such Pen Hospital (in Esplanade) dates back to the 1920s.

It is a bit odd that pen manufacturing did not start in Calcutta,[25] but in other parts of the country, like Andhra Pradesh and Tamil Nadu. There were also the Sanghvi brothers— Dwarakadas Jivanlal Sanghvi and Vallabhdass Jivanlal Sanghvi. After a stint in Rangoon (now Yangon, where they sold pens) and in Calcutta (now Kolkata, where they moved in 1941), the brothers moved to Bombay and started making parts for pens.[26] “In the beginning, the Nibs were imported from USA, under the brand names of Sita and Sity. However, as an error the supplier sent them a box of Nibs called Wilson instead. The war was a huge obstacle to sending the consignment back so they had no choice but to start making the pens with the un-returnable nibs. With the entire pen rebranded as Wilson, the pen sold far better than they expected and yet again another mistaken name was retained. By the mid-1940s the business grew and they had begun manufacturing all pens from scratch. The Manufacturing units moved to Andheri East and to Chakala. And they also introduced other brands such as the President. With almost a 1200 people as staff, there were people from almost all communities working together. A lot of women were hired for the first time. While the machines were worked by men, all the assembling of the pen was done entirely by women. Their daily salary at the time was around Rs. 3 to 4 per day.”

Wilson pens were extremely popular and it is often stated that a Wilson pen was used to write the Constitution, as in the title of Purvi Sanghvi’s piece. The first draft of the Constitution (26 November 1949) was indeed a work of calligraphy. Nandalal Bose and his students designed the borders. The actual Constitution was written by Prem Behari Narain Raizada (Saxena), who came from a family of calligraphers. In the process, he used 432 nibs of the No. 303 variety. Therefore, that draft of the Constitution was not written with a fountain pen; a dip pen was used instead. The Wilson pen was used by Ambedkar to write the draft of the draft, before it was handed over to Prem Behari Raizada. It is no longer possible to ascertain what happened to Ambedkar’s Wilson pen.[27]

Just as the Swadeshi brushed off on fountain pens, it affected the manufacture of ink. After all, a fountain pen cannot function without ink. One such brand was Sulekha, the Bengali word that translates as “beautiful writing”. Like Ratnam Pens, the trigger was again Gandhiji. Mahatma Gandhi’s letter, quoted earlier, mentioned a stock of “swadeshi” ink. Gandhiji passed on the thought about developing a Swadeshi ink, to Satish Chandra Dasgupta, who had retired then as the Chief Chemist of Bengal Chemicals. The thought was passed on to the brothers, Sankaracharyya Maitra and Nani Gopal Maitra, who set up the fountain pen manufacturing unit, Sulekha Works Limited, in Rajshahi (now in Bangladesh) in 1934. The first basic formulation of the ink came from Satish Chandra Dasgupta. There was also Camlin, which started a little earlier, in 1931.

In 1931, Dandekar and Company started with ink powders and tablets that were sold under the “Horse” brand. Since a camel has the reputation for enduring long trips across deserts, the “Horse” brand was replaced by the “Camel” brand. In 1946, “Camel ink” became Camlin and this used to be produced from a factory in Mahim (in Mumbai). In those initial years, ink was often in the form of powders and tablets, not liquid. The first ink that was produced was not by Sulekha Works nor by Dandekar and Company. That record is held by Krishnaveni Inks in Madras, from the year 1920. When World War II dislocated supplies from abroad, there were many units that started to produce fountain pen ink and catered to the demand, both civilian and military.

As for nibs, there is a list of 12 “Indian” or “Swadeshi” nib manufacturers in 1933:[28] (1) C. M. Karmakar and Company, Comilla; (2) F. N. Gooptu and Company, Calcutta; (3) Ideal Pen Works, Sialkote; (4) Ishwar Singh, Lahore; (5) Kulkarni Brothers, Bombay; (6) M. Hirday Narain, Lucknow; (7) Model Industrial, Agra; (8) Nib Manufacturing Company, Bombay; (9) Puri Iron Works, Gujrat, Punjab; (10) Tambat Brothers, Gwalior; (11) V. S. Ball and Company, Bombay; and (12) Waise Brothers, Sialkot. These must have been nibs for dip pens, not fountain pens. The nib manufacturers mentioned by R. N. Saha do feature in this list. Gujrat means the Gujrat in Pakistan and he seems to have got the location of Tambat wrong.

At the time of Independence, the “Indian” and the “foreign” co-existed and there was no reason why India should not establish its presence in the manufacture of fountain pens and fountain pen ink. But policy proved to be a hindrance.

3: The fountain pen promise

Before the economic reforms and liberalisation, there used to be a popular opinion that Indian fountain pens were more of fountains than of pens. This was due to policy-induced distortions.

To convey a flavour of the times, we will begin this section with a quote from a case before Bombay High Court (A.V. Venkateswaran vs Ramchand Sobhraj Wadhwani). The judgement, delivered by the Bombay High Court in 1961, was on appeal by the customs department against order of a Division Bench of the Bombay High Court. To quote from the judgement:“The respondent (Ramchand Sobhraj Wadhwani) carries on business in Bombay and he was granted on August 18, 1954, a licence under the Imports & Exports (Control) Act, 1947, for the import of fountain-pens at not less than Rs. 25 C.I.F. value each from soft currency area, up to a defined amount. He placed an order for the import of Sheaffer pens from Australia and a consignment of these was received by air in Bombay in October 1954. The fountain-pens thus imported had nibs which were gold plated and also caps and clips of similar composition. The question in controversy relates to the rate of duty to be charged on these imported pens. The Schedule to the Indian Tariff Act, 1934, has an item numbered 45(3) in relation to the article described as “fountain pens complete”, the rate of duty being 30 per cent., ad valorem. It was the case of the respondent that the imported goods fell within this item and were liable to be charged with duty at that rate. The Customs authorities, however, considered that the consignment fell within the description “articles plated with gold or silver” being item 61(8) on which duty was payable at 78|- per cent. The Assistant Collector of Customs adjudicated the duty on this latter basis and thereafter the respondent having filed an appeal to the Collector of Customs, the levy was upheld by order dated February 22, 1955.” Mr Wadhwani went to court, and the Bombay High Court held: “on any reasonable construction of the items in the Schedule to the Indian Customs Tariff, fountain-pens did not cease to be fountain-pens because they contained parts which were plated with silver or gold and that so long as they were ‘fountain-pens complete’, subject to any exceptional cases of which this was not one, only duty at 30 per cent, under item 45(3) could be levied.” The customs department appealed and this eventually led to the 1961 judgement, where a bench consisting of P Gajendragadkar, A Sarkar, K Wanchoo, K Dasgupta and N R Ayyangar upheld what the single judge had already ruled.

We used the term, “policy-induced distortions”. There were four of these: (1) Quantitative restrictions on imports; (2) Import duties; (3) Reservations for the small-scale sector; and (4) Exchange controls. Of these, (1) and (2) have been mentioned in the judgement.

Tariffs become relevant only if an item can be freely imported. Until quantitative restrictions on imports were eventually eliminated and replaced by tariffs, most items imported required an import licence. Few items were on OGL (open general licence). That expression OGL, used in Indian export and import policy, is a bit of an oxymoron. Contrary to a normal English language interpretation of the term, OGL actually meant a licence was not required. Anyone could freely import it, subject to the payment of appropriate import duties. Stated simply, items were divided into OGL, restricted, (where a specific import licence was required) and prohibited. OGL was a bit like a positive list. If an item was not on the list, it specifically required a license for importing. In those early years, much of legislation and policy was inherited from a period of war-time shortages and the 1939 Defence of India Rules. This was also true of the Imports and Exports (Control) Act of 1947, which gave those licensing powers, a piece of legislation mentioned in the court judgement cited. This was “An Act to prohibit or control imports and exports” because “it is expedient to prohibit, restrict or otherwise control imports and exports”. What is interesting is that when originally enacted in 1947, there was the qualification “for a limited period” attached to the legislation. That bit was excised in 1971. As was true of many other pieces of legislation, statutes meant to be temporary, entered into the statute books permanently. Fountain pens are consumer goods. Therefore, free imports of fountain pens, without licensing, had to wait till April 2001, when India phased out all quantitative restrictions (QRs) on imports. India has been a founder member of GATT (General Agreement on Tariffs and Trade) since its formation in 1948. GATT principles prohibit use of QRs. However, Article XVIIIB allows leeway to countries that face balance of payments (BOP) problems. Countries with BOP problems can deviate from that principle of eliminating QRs. This BOP argument and the use of Article XVIIIB became untenable in April 2001. It is the reason QRs had to be eliminated. Having signed the 1948 GATT agreement, in 1954 invoked Article XVIIIB and sought the flexibility to impose QRs on imports.[29] This waiver from commitments was sought for eight items: (1) canned fish; (2) wine; (3) toothpaste, tooth powder, talcum powder, shaving soap and shaving cream; (4) lithopone; (5) coal-tar dyes; (6) glass beads and false pearls; and (7) safety razors and parts. That is a list of seven items. The eighth was fountain pens and parts.

Today, if one reads the import and export policy documents of that period, they seem to belong to another world. For instance, there was an import replenishment scheme for registered exporters: “This Appendix contains the description of export products covered by the import policy for Registered Exporters, the percentage of import replenishment and materials allowed for import against each product as well as other conditions relating thereto.”[30] If you were a registered exporter who was exporting, a certain percentage of the value of exports would be allowed to import inputs, even if imports of those inputs were prohibited otherwise. Accordingly, in 1988-91, exporters of “fountain/ball point pens, ball point pen refills, sign pens, fibre tip pens (all types), micro tip pens, roller-writer pens and parts thereof, and fountain pen nibs (including stainless steel fountain pen and nibs (except filter and tips of fountain pens)” were permitted to import 20 percent of the value of imports in the form of steel balls, stainless steel coils/strips not exceeding 100 mm width, nickel, electroplating salts and brighteners excluding sodium cyanide, cellulose acetate moulding powder, polyethylene moulding powder as packing material, ball point refills, clips for fountain and ball point pens, metal caps and barrels for pens made of gun metal, silver sterling gold-plated, effaceable types of sketch pen inks in concentrated form, nigrosine dyes and synthetic fibre tips and filters for pens. For synthetic fibre tips and fillers for pens, the replenishment rate was 10 percent, not 20 percent. These are quotes from the 1988-91 policy, announced in 1988, when some amount of import liberalisation had already taken place. Nevertheless, they are symptomatic. Classified as consumer goods, import liberalisation for fountain pens did not occur till April 2001.

Today India follows the eight-digit harmonised system of customs nomenclature. The more the number of digits, the finer is the description. Fountain pens will figure somewhere under the four-digit head of 9608. 9608 includes all kinds of pens. We know it is a fountain pen at the five-digit level, when it becomes 96083. Beyond 96083 and moving on to the sixth digit, there are finer classifications of fountain pens. The import duty structure has elements of a basic customs duty, surcharge, cess, and IGST (Integrated Goods and Service Tax). The current basic customs duty on fountain pens is 10 percent and IGST is 18 percent. Ignoring the surcharge and cess, which are not permanent, the import duty on fountain pens is 28 percent. The basic customs duty has been 10 percent since 2007. Prior to that, it was 52 percent in 1996, 45 percent in 1997 and 1998, 40 percent in 1999, 38.5 percent in 2000, 30 percent in 2002 and 2003, 20 percent in 2004, 15 percent in 2005 and 12.50 percent in 2006. In addition to the QR phase-out, import duties have also been slashed.

Let us now move on to small-scale sector reservations. The statutory powers for these came through the Industries (Development and Regulation) Act (IDRA) of 1951. This statement is only partly true. The 1951 IDRA gave the government the powers to introduce industrial licensing. Until IDRA was amended in 1984, the government did not possess any statutory powers for small-scale sector reservations. However, no one ever challenged small-scale sector reservations in court. The best introduction to the policy of reservations is the now-forgotten Abid Hussain Committee.[31] “The policy of reservation was primarily initiated in 1967 as a promotional and protective measure for the small scale sector vis-à-vis the large scale sector. Under this policy selected products are identified for exclusive production in the small-scale sector…. No new unit in medium or large scale sector is allowed to be set up after the date of reservation, nor any further capacity expansion in the existing medium or large scale units is permitted. All further expansion or capacity creations reserved for the small scale sector. The medium or large scale industrial units can continue to manufacture reserved items in cases as mentioned below: (a) The existing medium or large unit which had already been manufacturing an item when it is put on the reserved list. In such a case the unit has to obtain a Carry on Business (COB) Licence from the Ministry of Industry. The capacity of the unit is pegged at the highest production level achieved by the unit in the last three years preceding the date of reservation of the product. (b) If the existing SSI units manufacturing reserved items graduate by their process of growth into medium / large scale, such have to obtain a COB Licence wherein the capacity is pegged with respect to the date when it became incumbent on the unit to apply for and obtain on the unit to apply for and obtain a COB Licence… The Industries Development and Regulation Act, 1951 has been amended in 1984 to give statutory backing to the policy of reservation empowering the government to reserve selected items for production by the ancillary or small scale industrial undertaking. The amendment also provided that the central government would constitute an Advisory Committee with a view to determining the nature of any article or classes of articles that may be reserved for production by the ancillary or small scale industrial undertaking.”

Over a period of time, the number of items reserved for production by the SSI (small-scale industry) sector shot up from 47 in 1967 to 504 in 1976 and 873 in 1984. These numbers are under the old National Industrial Classification (NIC). After the Micro, Small and Medium Enterprises Development Act of 2006, the SSI nomenclature has of course been overtaken. There has indeed been some liberalisation. First, definitions of SSI/MSME have become wider. Second, with an equity limit, FDI is permitted in the SSI sector. Third, large enterprises can also invest in the SSI sector, provided that at least 75 percent of production is meant for exports. Nevertheless, reservations still remain for the small-scale sector. In 1967, when the policy of reservations started, fountain pens were reserved for production by the small-scale sector. Even today, if the price of the fountain pen is less than Rs 100, it is still reserved for production by the small-scale sector. Back then, small-scale sector reservations were courtesy the Second Five Year Plan (1956-61), not the First Five Year Plan (1951-56) and the intellectual support was provided by the Karve Committee.[32] Yet one should be careful. The First Five Year Plan, the Second Five Year Plan, the Third Five Year Plan (1961-66) and the Karve Committee talked about policies to support the small-scale sector, not reservations. Reservations were actually introduced during the Plan Holiday, in between the Third Five Year Plan and the Fourth Five Year Plan (1969-74). No one quite explains who decided to introduce SSI reservations in 1967 and how the original list of 47 items (later expanded much more) was drawn up.

Many years ago, the Council of Scientific & Industrial Research (CSIR) produced a publication that was a mine of information. It was appropriately titled, “The Wealth of India” and the 1965 version, just before reservations set it, has a lot of interesting information on fountain pens, nibs and ink.[33] “The fountain pen industry had its beginning in the early thirties, but it is only during the last decade or so that it has made substantial progress. In 1964 there were 15 organized manufacturers of fountain pens. Two of them, namely, Pilot Pen Co. (India) Ltd, Madras, and Rightaids (Orient) Pvt. Ltd, Madras, have foreign collaboration. Other manufacturers are: Dhiraj Pen Mfg Co., Bombay; Mahatre Pen & Plastic Industries Ltd, Bombay; Gujarat Industries, Bombay; G. D. S. Chowdhury, Delhi; Exen Industries, Bombay; K. V. Ratnam & Bros, Rajahmundry (Andhra Pradesh); K. V. Brahman & Sons, Bhimavaram (Andhra Pradesh); Jupiter Industries, Delhi; Prakash Metal Works, Bombay; Leader Fountain Pen Works, Rajahmundry; Zebra Instruments, Bombay; Asoka Pen Works, Tenali (Andhra Pradesh); and Seth M. B. Kapur & Co., Modinagar….Fountain pens are also manufactured by many small scale units in the country. In 1962, there were about 210 small units with an annual production capacity of 4,765,000 dozen pens. The state-wise distribution of these units is as follows: West Bengal, 44; Maharashtra, 40; Andhra Pradesh, 31; Uttar Pradesh, 28; Madras, 25; Delhi, 17; Punjab, 13; Gujarat, 5; Rajasthan, 3; Bihar, 2; Kerala and Madhya Pradesh, 1 each….The total labour employed in the organized sector of the fountain pen industry is 3,000; the number employed in the small scale and cottage units in the southern zone is 330. An ad hoc committee of fountain pen manufacturers has been set up at the instance of the Government of India to inquire into the quality of fountain pens with a view to ascertaining and eliminating the causes leading to the production of low grade pens.” Note that this was written before reservations and that quality was an issue even then.

CSIR’s publication also gives figures on estimated production of fountain pens, for the period 1958 to 1963. There were yearly fluctuations, but an average figure for annual production was around 10 million fountain pens. The cited production capacity of the small-scale sector (4,765,000 dozen pens) translates to 57.18 million pens a year. Even though this is production capacity and not actual production, this is a staggering number.

Among the larger players, Pilot Pen Company (India) was of course the Indian subsidiary of Pilot, the Japanese pen maker. This Indian subsidiary was incorporated on 21 July 1952. Right Aids Orient was a TTK (T.T. Krishnamachari) group venture, incorporated in Madras. However, the first factory was set up in 1951 in Bangalore, not in Tamil Nadu. That is because there was electricity shortage in Tamil Nadu then. Unlike Pilot Pen Company (India), Right Aids Orient was not a subsidiary. It had a license to manufacture the Waterman brand of pens, as other Indian manufacturers would also do later. We have already mentioned the Sanghvi brothers, Dwarakadas Jivanlal Sanghvi and Vallabhdass Jivanlal Sanghvi, and Wilson pens. Dhiraj Pen Manufacturing Company was set up by Vallabhdass Jivanlal Sanghvi. Mhatre Pen Plastic Industries Private Limited was established in 1951, though the antecedents go back to 1933.

At that time, Pilot sold a brand named “Champion”. From an IPR (intellectual property rights) violation case filed by Pilot, we get to know the brand names under which some of the Indian pens were sold.[34] This was a set of cases on which the Madras High Court passed judgement in 1966. “The plaintiff, Pilot Pen Co., claims to have absolute copy right in a new and original design in respect of fountain pen clips, having registered their design under No. 101410 dated 28-9-1959 under the Indian Patents and Designs Act 1911. It is the plaintiff’s allegation that the several defendants have been manufacturing and marketing fountain pens in the name and style of Champion Registered 81 “President” and “Mahtre Writer” respectively with clips exactly similar to or at any rate of colourable imitation of the plaintiff’s registered design and have thus committed unlawful infringement and piracy of the plaintiff’s design and that the several defendants have refused to comply with the plaintiffs demand to stop committing the infringement and submit accounts with regard to sale of these pens fitted with clips having the infringing design….In the written statement filed in C.S. 74 of 1963 by the defendant Mahtre Pen and Plastic Industries Pte Ltd. they contend that the plaintiff’s design is neither new nor original, that the plaintiff and their associates in Japan had themselves sold fountain pens with slips in the same or similar forms design, shape or configuration prior to the date of the registration of the design and that the said design does not contain any characteristics over and above the fundamental form of a clip used for fountain pens which is in substance a mere mechanical device. Even so, there is no colourable or fraudulent imitation and the defendant fit their fountain pens with clips bearing the names “Mahtre writer” “Plato” and many others.”

The judge ruled that was no IPR infringement. One of the brands sold by Dhiraj Pen Manufacturing Company was thus “President”, Mhatre Pen Plastic Industries sold “Mhatre Writer” and “Plato” and Gujarat Industries sold “Ashok” and “Service”. But Mhatre sold pens under other brand names too. For example, after Eversharp was acquired by Parker Pen Company in 1957, Mhatre sold “Doric”, manufactured under a licence and it also had own brands like “Writer” and “Clipper”. Subsequently, under licences, it also made pens for Waterman and Swan. Mhatre Pen Plastic Industries, Gujarat Industries and Dhiraj Pen Manufacturing Company closed shop in the 1980s, or moved on to other products. However, Mhatre left a legacy as Ravlon. There seems to be no record of what happened to G. D. S. Chowdhury.

What happened to Exen Industries is known from a case before the Supreme Court.[35] This too, was a case on imports, specifically import licensing. “The facts are as follows. The appellant firm which is engaged in the manufacture of fountain pens, ball pens etc. was constituted of three partners, namely, K.N. Vora, J.L. Mehta and A.M. Bhuta, After retirement of some of the partners, the firm consisted of only two persons H.T. Vora and C.J. Mehta in November 1953.” The Vohra-Mehta venture continued as Exen Industries, but was dissolved in 1963. With another partner, Vora continued with Exen Industries. Mehta started to make fountain names under the name of Premier Products. There was a brand known as “Sulekha”, not to be confused with the ink. We have already spoken about K. V. Ratnam and K. V. Brahman & Sons (Bhimavaram) was linked to K. V. Ratnam. Kosuri Erayacharya from Rajahmundry had two sons, Kosuri Venkata Ratnam (K V Ratnam) and Kosuri Venkata Brahmam (K V Brahmam). K. V. Brahman set up his fountain pen manufacturing unit in Bhimavaram and these were sold as “Brahman” pens. There seems to be no record of what happened to Jupiter Industries either. Prakash Metal Works still exists, but has moved away from making fountain pens. No record seems to exist of Leader Fountain Pen Works, Rajahmundry. Zebra Instruments has closed down. Asoka Pen Works (Tenali) was a small-scale unit that closed down. It used to sell “Asoka” brand pens, not to be confused with “Ashok” sold by Gujarat Industries. No record seems to exist of what happened to Seth M. B, Kapur, Modinagar.

Although CSIR is a credible source, there seem to be gaps in what it described as “organized” sector production of fountain pens. “Organized” is a legal term and an enterprise is “organized”, under the Factories Act, depending on whether it uses power and depending on whether the number of employees is more or less than 10/20. It is doubtful that CSIR used the word “organized” in that strict legal sense. Otherwise, Asoka Pen Works (Tenali) would not have been included in “organized” and some others would not have been excluded. Ministry of Labour’s publication for 1958 is a better source.[36] This has a category of large industrial establishments, with pen and pencil making clubbed together. If one excludes those that are obviously connected with pencils, one has the following list. (1) Ratnam Pen Works, Rajahmundry; (2) Sastry Pen Works, Tenali; (3) Raynar Pen Works, Guntur; (4) Air Mail Pen Company, Bombay; (5) Popular Pen & Clip Industries, Bombay; (6) Dhiraj Pen Manufacturing Company, Bombay; (7) Balkrishna Pen and Plastic Manufacturing Company, Bombay; (8) Pankaj Pen Industries, Bombay; (9) National Pen Company, Bombay; (10) Venus Pen Company, Bombay; (11) Wimco Pen Company, Bombay; (12) Pilot Pen Company of India Limited, Madras; (13) Radar Fountain Pen Factory, Tiruvellore; (14) Prakash Pen, Kanpur; (15) Seth M. B. Kapoor and Company, Modinagar; and (16) Indian Pen and Allied Industries Company, Calcutta.

At that time, given the importance of manufacturing in Maharashtra, Bombay’s dominance is understandable, and of course Andhra Pradesh’s. There are available figures from the Labour Ministry on the average number of workers employed. Most of the 16 listed enterprises employed less than 20 workers. With more than 200 workers, Dhiraj and Balkrishna were large. Pilot employed around 150 and the average number employed in Kanpur and Modinagar was around 30. Balkrishna was also part of the Wilson group of companies, that is, the Sanghvi brothers. But the branding of the pens was different. Balkrishna produced “Wilson”, while Dhiraj produced “President”. Airmail Pen Company was established in 1951 by Mohan L. Mirchandani and has two brands, “Wality” and “Airmail”. National Pen Company is what exists today in the form of Flair Pen and Plastic Industries Private Limited. Wimco also has a successor in Flair and the “Flair” brand, established by Wimco in 1976. The Rathod family, now associated with Flair, was originally associated with Wimco. India Pen and Allied Industries was established in 1944.

To reiterate, the CSIR list was from 1965 and the Labour Ministry one from 1958. Both pre-date the 1967 SSI reservations. And both do not mention a few other fountain pen making enterprises set up in the 1960s, before 1967. In 1963, there was Davindra Kumar Jain’s Luxor, which introduced a fibre-tip pen in 1966 under the brand name of “Artist”. Camlin (now Kokuyo Camlin) started making fountain pens. Industrial Research Corporation (BRIL) was set up in 1964. It may have been started as a manufacturer of ink, but soon moved on to fountain pens. There was Deccan Pens, not mentioned in the CSIR or Labour Ministry lists. There was a cottage industry of sorts in Calicut (Kozohikode). As in some earlier examples, M. Haneefa Rawthar used to sell fountain pens there. Perforce, he had to start repairing them and Kim and Company was set up as a repairing centre in 1942. In 1955, Kim and Company started manufacturing fountain pens.

Before the 1967 reservations, there were thus different categories of fountain pen makers: (1) Foreign ones like Pilot; (2) Very large Indian units like Dhiraj and Balkrishna; (3) Large Indian manufacturers, “large” in the sense of being under the purview of the Factories Act; and (4) Small manufacturers, without SSI reservations. Benefiting from protection from imports, the spread of education and increased demand, they thrived and co-existed. Table 1 gives an idea of how much these fountain pens sold for in 1963.[37] These are wholesale prices, per dozen fountain pens. Sometimes, there is a range, because the model and the quality of the nib (gold versus steel) differ.

Table 1: Prices of Fountain Pens

| Brand name |

Price in Rs/dozen |

| Pilot |

57-186 |

| Champion |

132 |

| Swan |

120 |

| Black Bird |

85.50 |

| Wilson |

36-66 |

| Doric |

18-72 |

| Clipper |

22-45 |

| Plato |

24 |

| President |

15-18 |

Different companies and different brands co-existed in different slices of the market. “The popular brands of fountain pens being manufactured are: Pilot, Waterman, Wilson, Lux, Dodge, President, Olympic, Liberty, Parle, Homer, Plato, Hunter, Doric, Champion, Ashok and Mayor.”[38] In addition, “Only costly pens are imported.” Given the import restrictions, this was understandable. Indeed, given the import restrictions, it was odd that imports of fountain pens took place at all. Imports dramatically dropped from 2,428 pens in 1960-61 to a measley eight in 1962-63. In 1962-63, the average cost of an imported pen was Rs 17. For a dozen of these, the expense would have been Rs 208, far in excess of the most expensive 14-karat gold pens produced in India. The cost of the imported pen naturally included import duties. With severe import restrictions, smuggling was inevitable. In later years, these were via Nepal. In the initial years, they were often through former French or Portuguese territories. The sharp drop in imports after 1961 was probably because of import restrictions, but may also have had something to do with Goa becoming part of the Union of India in 1961. Oddly, exports of fountain pens also dropped sharply from 610,258 pens in 1960-61 to 358,515 pens in 1962-63. Even more oddly, these exports of fountain pens were for less than 1 rupee a piece, that low price partly explained by export subsidies.

Before concluding this section, one should also mention nibs and fountain pen ink. “Gold nibs used in fountain pens are produced by Pilot Pen Co. (India) Pvt. Ltd., Madras; Rightaids (Orient) Pvt. Ltd, Madras; K. V. Ratnam & Bros, Rajahmundry; Leader Fountain Pen Works, Rajahmundry; and K V. Brahman & Sons, Bhimavaram. Gold-plated stainless steel nibs are manufactured by 9 organized manufacturers of fountain pens and 13 small units in Sattur (Madras State).”[39] The CSIR listing does not mention Ambitious Gold Nib Manufacturing Company, set up a little later in 1965. For that period, 1958 to 1963, gold nibs produced were limited in number. Most nibs produced were made out of steel. Gold-plated iridium or steel nibs were roughly half the number of steel nibs produced. Small numbers of nibs were imported and exported.

Sattur was a major centre for making fountain pen nibs, though these were small-scale family businesses, cottage industry, so to speak. Since this was small-scale, robust figures are difficult to get. But there seem to have been around 250 enterprises making fountain pen nibs in Sattur alone, with steel imported from the United States (US) and the Soviet Union. These are figures from the 1960s, when Sattur had a large market share in nibs manufactured domestically. However, a similar figure is also cited for the 1980s. But that was a long time ago, and the number has dropped dramatically since then. Sattur has been important enough for dissertations to be written on it.[40] This dissertation, authored in 2013, mentioned 53 nib-making units in Sattur, though the number may have declined further since then. The dissertation says that Thiru Rajagopalasari migrated from Kerala and set up the first nib-making unit in Sattur in 1941.

The lobby for protection was greater for fountain pen ink than for fountain pens. Krishnaveni Inks, Sulekha Works and Dandekar and Company have been mentioned earlier. There was also Chelpark and the ubiquitous “Quink” brand of fountain pen ink, manufactured by Parker Pen Company. After the collaboration with the Chellaram family, this became “Chelpark”.

In 1950, the Tariff Board produced a report on the fountain pen ink industry.[41] This section ends with a long quote from this report, both because it has an excellent description of the state of the fountain pen ink industry and that it illustrates the kind of calculation that went into computation of import duties, to ensure a level playing field.

“The first factory established in India to produce fountain pen ink on a commercial scale was the Krishnaveni Inks set up in Madras in 1920…Between 1920 and 1930, a few more units were established in the State of Madras and elsewhere. During the period from 1930 to 1940, ten more units were established in different parts of the country. Thus, before World War II, there were more than a dozen indigenous factories producing fountain pen ink. It was, however, the advent of World War II that gave a stimulus to this industry to develop rapidly. This was mainly due to the disorganization of world trade and lack of shipping facilities, resulting in the reduction of imports of fountain pen ink. The indigenous industry which had so far suffered from keen competition from the imported inks now began to meet not only the requirements of the civilian population but also those of the two million personnel of the defence services stationed in the country. During this period, the indigenous producers also exported the article to the neighbouring Eastern countries. It will thus be seen that the main expansion of this industry took place during war-time and the immediate post-war period. ..However, during the early post-war period, the production of indigenous fountain pen ink was considerably curtailed due to the keen competition offered by large quantities of the imported material which was being sold at comparatively low rates. We have, however, been informed by the industry that as a result of the total banning of imports of fountain pen ink since July, 1949, the position of the industry has improved during the last few months…The number of known units at present is about seventy-seven, and they are distributed all over the country, but South India and the States of Bengal and Bombay claim the largest numbers. The industry is mainly composed of small units. The amount of capital employed in the different units ranges from Rs.250 to Rs. 2 lakhs; in the majority of cases, however, the amount invested is below Rs. 20,000. The number of workers employed in the different units varies from 2 to 5 and in a few cases from 10 to 50. It may also be noted that the industry has been established mainly by educated middle class people with comparatively small financial resources.[42]…The countries from which fountain pen inks are mainly imported into India are U.K. and U.S.A. The brands of imported ink which are popular in the country are ‘Swan’, ‘Waterman’, ‘Quink’, ‘Skrip’ and ‘Stephens’….It will be seen that fountain pen ink was on O.G.L. during the period January-June, 1949. The manufacturers stated before us that his liberal licensing policy resulted in large imports of the article being brought into the country and heavy stocks built up, which will last for a considerable time…Since, however, the entire needs of the Indian Union can be met by the indigenous manufacturers, we recommend that so long as the policy of licensing has to be continued for balance of payment considerations, the desirability of maintaining and expanding the indigenous production of fountain pen ink should be kept in view and the quantum of imports regulated accordingly.” The report recommended an import duty of 37.5% on imports of fountain pen ink. This would “cover the difference between the estimated fair selling price of the indigenous product and the landed cost without duty of the imported article…Moreover, as long as the present import control continues, it will also serve as a most effective measure of protection to the industry and give it an opportunity to improve its power of competition.”

There could not have been a better articulation of the infant industry and import substitution argument.

4: The fountain pen becomes a fountain

Until the introduction of SSI reservations in 1967, one does not form the impression that the “unmake in India” was going to occur in India for fountain pens, or that fountain pens would become more of fountains and less of pens. A valid argument can of course be made about the absence of import competition. The first nail in the coffin was SSI reservations. As mentioned earlier, reservations were introduced during the Plan Holiday, in between the Third and Fourth Five Year Plans. The former Planning Commission was not responsible for suggesting reservations and 1955 Karve Committee talked of purchase preference from SSI and support for technological up-gradation. But reservations were not mentioned, nor even price preferences for purchases from SSI. In 1967, fountain-pens were in that initial list of 47. This prevented fresh entry from large enterprises and since existing large enterprises were not asked to close down (when reservations were introduced), cushioned them against competition.

The second nail in the coffin was the Foreign Exchange Regulation Act (FERA) of 1973, a more draconian piece of legislation than its antecedent, FERA of 1947. FERA 1947 also owed its origins to war-time shortages and the Defence of India Act of 1939, though it became a part of the permanent set of statutes. There were several arguments that suggested FERA of 1947 be tightened up. For instance, there was a 1972 report of the Law Commission.[43] In 1971, there was a study team chaired by M. G. Kaul to examine leakages through foreign exchange manipulation. That bit of history does not concern this monograph. Suffice to say, FERA 1973 was passed and there were sections (repealed through an amendment in 1993) requiring dilution in equity to 40 percent. More than 40 percent required specific approval from RBI and diversification. This led to high-profile exits, like IBM and Coca Cola, while Hindustan Lever chose to diversify. Note that fountain pens figured in the consumer goods category, where FDI was not required as essential. “FERA affected already-established foreign companies in India that had foreign equity stakes exceeding 40 per cent, and it applied regardless of a firm’s initial terms and conditions. FERA also outlined that all companies operating in India (with the exception of foreign airline, shipping, and banking companies) would be incorporated under the Indian Companies Act, which would curb tax-free outflows of profits. Additionally, the maximum foreign equity percentage stake differed by industry. Violations of FERA would incur criminal charges. Out of the 881 companies that applied to the RBI, only 150 companies were allowed to keep a higher level of foreign equity than the prescribed cap; the others diluted to fit the ambit of FERA. Companies that found the terms unacceptable began to wind up operations in India. Fifty-four companies applied to exit India by 1977–1978 and nine companies applied to exit in 1980–1981.”[44] One thinks of FERA 1973 only in terms of what it did to existing “foreign” companies. Its negative impact was no less serious for possible future entrants.

Stated simply, “imports”, “foreign”, and “large” were all undesirable; “small” was beautiful. This meant explicit encouragement to fountain pen enterprises of the cottage industry kind. Fountain pens differ from old dip pens because there is a reservoir of ink. Other than the onslaught of ball pens, technology around that reservoir also changed, especially since 1970s. From eye dropper pens, technology moved to converters or other suction mechanisms and cartridges. Material for the body moved from ebonite to the more attractive acrylic. Technology has costs and there are economies of scale in production, as well as marketing. If one constrains that process, one is reduced to that truism about Indian fountain pens being more of fountains and less of pens. There is limited USP in creating a niche out of hand-made, ebonite eye-dropper pens.

In addition to FERA, there was Chapter V-B of the Industrial Disputes Act. The Industrial Disputes Act was enacted in 1947. This introduced rigidities in the organised labour market, that is, that part of the labour market that was under the purview of the Industrial Disputes Act. This meant enterprises that were covered by the Factories Act of 1948. For example, Section 9A of the Industrial Disputes Act made technological upgradation extremely difficult. Additional rigidities crept in over time. Chapter V, on strikes and lock-outs existed in the original piece of legislation. But Chapter V-A, on lay-off and retrenchment was inserted in 1964. Chapter V-B was inserted in 1976 and had special provisions on “lay-off, retrenchment and closure in certain establishments”. Stated simply, if the number of employees was more than 100, Chapter V-B required permission from the “appropriate government” before lay-off, retrenchment and closure. Chapter VA also had similar provisions. But under those, the appropriate government would have to be informed. In the case of Chapter VB, permission would have to be taken from the appropriate government. But it was not only about the Industrial Disputes Act. It was also about the broader tightening up of labour laws and their implementation.

Consider this quote:

“Fountain pens, ones that university students use for writing, you know, were in short supply. The participants asked the director of a fountain pen plant why he had not produced fountain pens. He replied that he had not been supplied with metallurgical materials. They asked the director of a steel mill why he had failed to supply the fountain pen plant with materials. He said: Because I did not get any iron ore from the smelter. The director of the smelter said that he had not gotten ore from the mine. The responsible official at the mine said: I produced some, but rail transportation was not available to the smelter. The railways minister was then summoned and asked: Why did you not transport the mineral ore? He said: Because we did not get any railroad ties from the Forestry Ministry. The Forestry Ministry replied that it did not have any gas to produce timber.”

One might think it is a description of India but it is not. It is a description of North Korea and what is described within quotes is from a meeting of the State Administrative Council in 1988 to discuss fountain pens.[45]

While India was not ever North Korea and the Indian economy was not ever the North Korean economy, both shared the characteristics of shortage economies. Import competition was ruled out. Domestic protection was precluded. Therefore, when the economy was opened up, post-1991, and consumers benefited from choice, inefficient domestic production was bound to exit. Therefore, one reads about the closure of manufacturers like Hilal in Hyderabad (with its Sultan brand), Asoka in Tenali, Misak in Hyderabad, and Kale Pens in Pune. Alternatively, one reads about Luxor, manufacturing brands like Pilot, Waterman and Parker under license, apart from diversifying from fountain pens to other office supplies. Contrary to popular impression, fountain pens are not quite dead. Ten percent of the market for writing instruments still consists of fountain pens. But what role do Indian brands have to play in that ten percent segment?

5: The churn and entry

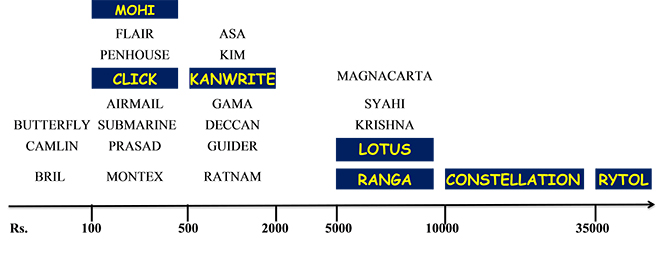

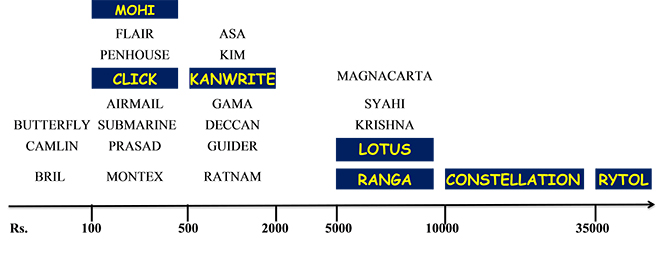

Competition inevitably means churn, entry and exit. Contrary to what one might think, there are quite a few Indian brands, though most of them are brands most people may not have heard of. In terms of vintage, there are some players who have been around since pre-Independence and have still not exited (Gem/Gama, Deccan, Camlin, Ratnam, Guider). A second generation was set up in the 1950s and 1960s (Airmail/Wality, Prasad, Motiram Doctor (Mohi) and BRIL. A third generation, often with better technology, was set up during the first stages of liberalisation in the late 1970s and 1980s – Ranga, Montex, Unique (Click) and Kanpur Writers (Kanwrite). Finally, in the last few years, there has been a fifth generation – ASA, Lotus, Syahi, Krishna and Rytol. The average price of a pen is difficult to indicate, because the same company can have different models. A gold nib will be more expensive than a steel one. The cost of the nib will depend on the tip and the plating. An eye-dropper pen will be cheaper than one that has a converter or a cartridge. An ebonite feeder, increasingly rare, will be cheaper than a plastic feeder. The material used in the body also determines the cost. With these qualifications, at the low end of the range, Camlin, BRIL and Butterfly sell at less than Rs 100 a pen, indeed closer to Rs. 30. There is a clutch of brands between Rs 100 and Rs 500 – Mohi, Flair, Penhouse, Click, Airmail, Submarine, Prasad and Montex. There is another clutch between Rs 500 and Rs 2000 – ASA, Kim, Kanwrite, Gama, Deccan, Guider and Ratnam.

Oddly enough, very few Indian brands focus on the fast-growing, Rs 2000 to Rs 5000 segment, which is where something like TWSBI dominates (its name means “Hall of Three Cultures”). Unlike India, Taiwan had no particular tradition in making fountain pens. For more than five decades, Ta Shin Precision was an OEM manufacturer for global brands, before TWSBI was established as its brand. TWSBI’s moulding facilities are state-of-the-art, large-scale and modern, something that India should have been capable of achieving, both in OEM and branding, given the traditional expertise. For that matter, Jin Gi Industrial Company, Penlux and International Writing Instrument Corp. (I.W.I.C.), all Taiwanese companies, have done the same for turning. Therefore, such OEM work goes to Taiwan. Nor did Turkey have any tradition in making fountain pens. Yet, Scrikks (established in 1963, with the first fountain pen produced in 1966) has become a brand and sell much more in the Indian market in the Rs 1000 to Rs 2000 band than Indian brands do. To return to the price range, in the plus-Rs 5000 category, there are Indian brands like Magnacarta, Syahi, Krishna, Lotus, Ranga and Constellation. Rytol’s base offering of Chairman’s Fountain Pen starts just short of Rs 40,000 and editions like the Russian Folklore series and Arteria sell for almost Rs 200,000. The figure indicates the present state of fountain pen manufacturing. It does not mention ITC’s entry with the low-end Octane, because the manufacturing is not internalised, but is outsourced to Ambitious. At the risk of some subjectivity, I have highlighted the names that I think have the potential to craft a ‘make in India’ fountain pen story.

Clearly, not all is well with the Indian fountain pen industry. Because of historical ‘unmake in India’ policies, the ‘make in India’ did not happen. There are several problems one can identify, despite pens like Mohi, Click, Kanwrite, Lotus, Ranga, Constellation and Rytol being fairly decent for their price range. First, there is a distribution issue, barring the strong distribution networks of Camlin, Flair and Montex. Few Indian brands feature in online sales (where Chinese brands like Jinhao dominate), in stationery shops like W. H. Smith, or in high-end and specialised pen shops like William Penn and Makoba. There used to be traditional distribution networks, with wholesalers offering advances to manufacturers and purchasing the pens.

Indian manufacturers have typically not been able to overcome the collapse of this traditional marketing network and its replacement by newer networks, electronic or otherwise. There are few Indian companies which have provisions for direct sales to customers through their own websites. On a related point, there are some (Guider, Lotus, Ranga) which are focused more on the overseas market than on the domestic one. One of these pens will sell for Rs 6,000 in India, but the equivalent of Rs 10,000 in the United States. One therefore understands the preference. Because of this distribution issue, some manufacturers (Butterfly, Penhouse, Submarine, Prasad, Montex, Kim, Gama, Deccan, Ratnam) are really local brands, rather than all-India ones. Second, most Indian manufacturers are MSME. This raises issues of finance not just for capital investments, but also working capital. Therefore, fountain pens are only manufactured through pre-orders. The manufacturing USP is perceived to be hand-made, not large volumes and modern manufacturing. Consequently, quality, consistency, finishing, packaging and branding receive short shrift. A lacquer finish, which adds sheen to the pen, costs only about Rs 350 a pen, but few Indian manufacturers will bother to do that. Eye-dropper pens routinely leak. Many manufacturers will not have a converter as a default, but only when asked for.

In Western markets, there is a premium on hand-made pens, but only when the requisite quality is present. The Jinhao X450 and X750 are available in online markets for Rs 500. While Chinese pricing policies may not be transparent, this does represent the competition. That is the reason only brands like Mohi, Click and Kanwrite offer some competition. Third, the traditional material for the body has always been ebonite, sourced from Tiruvallur. That may be a reason why many manufacturers are geographically located in the south. However, not only does ebonite have an ungainly odour, it is incapable of providing attractive designs and colours. The older manufacturers have generally refused to move away from ebonite. Therefore, among the 25 manufacturers listed, it might just be a matter of time before Prasad, Kim and Ratnam also make their exit.

Fourth, for the better quality pens, many materials are imported. The acrylic comes from the United States. The nibs come from Germany (Bock, Jowo) or China (Jinhao). The converters come from Germany (Schmidt). The import intensity of production can therefore be as high as 70 percent. The import duty on something like nibs (10 percent + 18 percent IGST) is the same as that on complete fountain pens. India not only imports pens, it also exports pens. The values are of course insignificant. In 2018-19, the value of imports of fountain pens was US$3.53 million. The shares of countries from which imports took place were 41 percent for UAE, 22 percent for China, 14 percent for Germany, 10 percent for Hong Kong, 4 percent for Japan and 3 percent for Taiwan. In 2018-19, the value of exports was 0.68 million US dollars. The market shares were 21 percent for USA, 13 percent for Nepal, 13 percent for Russia, 9 percent for Bangladesh, 9 percent for UK and 4 percent for UAE.

In discussing fountain pens, one often forgets that India does make some high-quality nibs, though not in Sattur. Ambitious makes and exports nibs for some of the foremost fountain pen brands in the world. Kanwrite also makes excellent nibs. Most nib manufacturers (Bock, Jowo, Schmidt, Ambitious) are OEM suppliers. Kanwrite is a rare example of a nib manufacturer that also sells nibs to retail customers. Some ink manufacturers are fairly decent too – Chelpark, Bril, Camlin, Daytone (Daylight Industries, set up in 1956) and Krishna.

Fountain pens and related items (ink, nibs, converters, feeders) may seem to be a quaint segment, buoyed only by nostalgia. Yet in that nostalgia-laden microcosm, we have unmake in India, and faint traces of change.

About the Author

Bibek Debroy is Chairman, Economic Advisory Council to the Prime Minister. He has written several books, papers and popular articles. He has a personal collection of around 150 fountain pens, most of which are Indian.

Endnotes

[1] Vol. 55 of Collected Works.

[2] Ibid.

[3] Vol.71 of Collected Works.

[4] Vol.74 of Collected Works.

[5] Vol.94 of Collected Works.

[6] Vol. 96 of Collected Works.

[7] “Revival of Village Industries,” Harijan, Vol.59 of Collected Works.

[8] All India Village Industries Association.

[9] Vol.71 of Collected Works. This also has excerpts from Prabhudas Gandhi’s letter.

[10] Ibid.

[11] Vol.58 of Collected Works.

[12] Vol.63 of Collected Works.

[13] Reported as a note to Gandhiji’s speech in Kodambakkam, Vol.70 of Collected Works.

[14] Vol.67 of Collected Works.

[15] This account is based on “Ratnam & Sons: Penning a Legacy,” Raj Samson, The Hans India, 18 November 2016, Nikita Doval, “To Pen the Swadeshi Narrative,” Open, 27 September 2019 and Tushar A. Amin, “India-made fountain pens thrive on global demand,” Money Control, 17 October 2013.

[16] Ratnam Pen Works still exists and manufactures fountain pens. Since the two brothers divided their businesses later, there is now a Ratnam Pen Works and a distinct Ratnam Ball Pen Works (which also sells fountain pens under the brand name Ratnamson). When President Ram Nath Kovind visited the Pablo Neruda Museum in Santiago on 31st March 2019, the press release by Rashtrapati Bhavan stated, “He gifted a special pen to the Museum made by the family whom Gandhiji encouraged to develop the first indigenous fountain pen in India.” Ratnam 302, still produced, is the one that was given to Gandhiji.

[17] Short Stories For Everyone, Inspiring incidents from Gandhiji’s Life: Selected from the book Everyone’s Gandhi, Gandhi Sevagram Ashram.

[18] “Reminiscences Of Gandhi, His Daily Life”, Mirabehn, 24th January 1948.

[19] Dr. Babasaheb Ambedkar : Writings and Speeches, Vol. 17 (Part-1), Education Department, Government of Maharashtra, 2003.

[20] “I Rewrote the Blurb of His ‘Pakistan’,” U. R. Rao, in, Ambedkar: The Attendant Details, selected and edited by Salim Yusufji, Navayana, 2017. John means John Thacker.

[21] Romance of Pen Industries, Being A Complete Manual for the Manufacture of Writing Materials, their History, Progress, and Effects on human advancement, with special reference to the Economics and Prosperity Problems of India, R. N. Saha, Baptist Mission Press, Calcutta, 1911.

[22] The Saha book gives a date of publication of 1795, though Hutton’s two volumes seem to have been published in 1815. Perhaps there was an earlier edition. A Philosophical and Mathematical Dictionary, Charles Hutton, London 1815.

[23] https://guiderpen.com/about-us/. The typos exist in the original text.

[24] A convenient summary of the case can be found. It is still remembered in Madras/Chennai and features in books on medical jurisprudence. in

[25] The only exception to this being Fanindra Nath Gooptu’s Gooptu Pens.

[26] See, “My Family Made The Pen That Wrote The Constitution Of India”, Purvi Sanghvi, The other mistaken name referred to in the quote is the name of a trading enterprise the Sanghi brothers set up.

[27] See, “Sifting Through History Looking for Ambedkar’s ‘Constitution’ Pen”, Pallavi Prasad.

[28] All India Swadeshi Directory, Allahabad Law Journal Press, Allahabad, 1933.

[29] See “India and GATT,” Economic and Political Weekly, 20 March 1954.

[30] Import & Export Policy, April 1988-March 1991, Volume I, Ministry of Commerce, Government of India, 1988.

[31] Report of the Expert Committee on Small Enterprises (Abid Hussain Committee), Ministry of Small Scale Industry, 1997.

[32] Village and Small-Scale Industries (Second Five-Year Plon) Committee (Karve Committee), Government of India, 1955.

[33] The Wealth of India, Industrial Products, Part VI, Council of Scientific and Industrial Research, Delhi, 1965.

[34] https://indiankanoon.org/doc/1409977/

[35] Exen Industries vs The Chief Controller Of Imports.

[36] Large Industrial Establishments in India, Ministry of Labour and Employment, Labour Bureau, 1958.

[37] Collated from The Wealth of India, Ibid.

[38] Ibid. Some of these brands are difficult to pin down now. Lux was probably a Waterman brand, Dodge was probably a Graf von Faber-Castell brand, Olympic was a local Indian brand, Liberty was probably from Cross, Parle must have been a local Indian brand and Homer sounds like Montblanc. But many of these may have been local Indian brands.

[39] Ibid.

[40] See, for example, The Problems and Prospects of Fountain Pen Nib Industrial Units in Sattur block of Virudhunagar District, Tamil Nadu, K. Thangaraj, Ph.D. dissertation, Madurai Kamaraj University, 2013.

[41] Report on the Fountain Pen Ink Industry August 1949, Board of Trade, 1950.

[42] This innocuous sounding expression about “educated middle class people” may have had significant implications in terms of being able to lobby and create protectionist pressure, much more than by fountain pen makers.

[43] The Trial and Punishment of Social and Economic Offences, Law Commission of India, 47th Report, 1972.

[44] “Charting Dynamic Trajectories: Multinational Enterprises in India,” Prithwiraj Choudhury and Tarun Khanna, Business History Review, Vol. 88, Spring 2014.

[45] Cited in, North Korea through the Looking Glass, Kongdan Oh and Ralph C. Hassig, Brookings Institution Press, 2000.

The views expressed above belong to the author(s). ORF research and analyses now available on Telegram! Click here to access our curated content — blogs, longforms and interviews.

PDF Download

PDF Download

PREV

PREV