This article is part of the series Comprehensive Energy Monitor: India and the World

This article is part of the series Comprehensive Energy Monitor: India and the World

The

first pilot project of underground coal gasification (UCG) in India was carried out in the Vastan mine block, Surat, Gujarat by ONGC (Oil & Natural Gas Corporation Limited) in collaboration with Gujarat Industries Power Company Ltd (GIPCL) in 2010. ONGC took up the Vastan Mine block site belonging to GIPCL in Nani naroli, Surat district, Gujarat as an R&D Pilot Project to establish UCG technology in collaboration with the

National Mining Research Center-Skochinsky Institute of Mining (NMRC-SIM), Russia. Agreement of Collaboration (AOC) to co-operate in the services, operations, development and research related to UCG in India with ONGC was extended up to March 2020.

A number of sites were jointly identified by ONGC and Neyveli Lignite Corporation Limited (NLC) for studying their suitability to UCG. These are Tadkeshwar in Gujarat and Hodu-Sindhari & East Kurla in Rajasthan. One more site was jointly identified by ONGC & GMDC (Gujarat Mineral Development Corporation Limited) in

Surkha in Bhavnagar district, Gujarat. The data of all the fields have been analysed for evaluating the suitability of these sites for UCG. All the sites have been found suitable for UCG exploration. Progress on the UCG projects has been slow, but could it become an option for decarbonising coal in India?

Basic Technology

Underground Coal Gasification (UCG) is the partial in-situ combustion of the coal seam to produce usable gas through the same chemical reactions that occur in surface gasifiers. This is achieved by

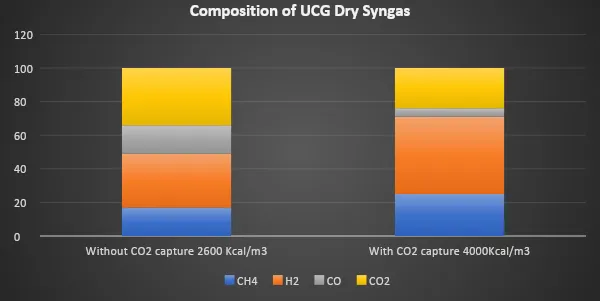

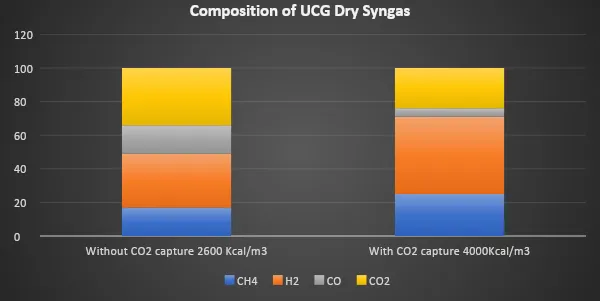

injecting steam and air (or oxygen) into the coal seam which is then ignited to initiate gasification. Typically temperatures above 1000°C are required for the gasification to proceed. The products and by-products of gasification vary depending upon the nature of coal, the temperature, the pressure and also whether air or oxygen is used. The product gases (synthetic gas or syngas) consist

primarily of carbon monoxide (CO), carbon dioxide (CO2), hydrogen (H2), methane (CH4) and to a lesser extent hydrogen sulphide (H

2S) and some higher molecular weight pyrolysis products. Regardless of use, syngas has to be cleaned up using commercially available technologies to remove impurities such as particulates, tar and sulphur compounds such as

H2S and carbonyl sulphide (COS) to make it usable.

Products of UCG

Electricity

The hot syngas from UCG can be used to

make steam to drive a steam turbine that generates electricity or it can be combusted to produce steam to drive an electric turbine. Syngas can also be directly fed into a fuel cell that can tolerate CO to generate low voltage electricity that can be stepped up and fed into the grid.

Chemical Feedstock

Syngas can be used as chemical feedstock (after its H

2 to CO ratio is suitably balanced) to produce

methanol, hydrogen, ammonia and other chemical products using the Fischer-Tropsch process. Central Institute of Mining & Fuel Research (CIMFR), India has identified methanol and Liquid Petroleum Gas (LPG) as potential products of gas produced from UCG operations.

CIMFR produces 5 litres of syngas a day from its pilot UCG project and converts 1.5 tonnes of coal to methanol in its methanol rectifier.

Production of Hydrogen

A stronger case for UCG lies in the fact that coal is the obvious

source for hydrogen which is potentially an important near zero carbon energy carrier of the future. UCG as a hydrogen generator coupled with a solid oxide fuel cell (SOFC) to generate electrical power directly has been

studied by Indian experts. Integration with SOFC gives two specific advantages: (1) The anode exhaust from SOFC that has high operating temperature can be used to produce steam required for the operation of

UCG as well as for the reforming of the syngas for the SOFC (2) SOFC can also serve as a selective absorber of oxygen from air for an efficient system of a carbon-neutral electrical power generation from underground coal. Thermodynamic analysis of the integrated system shows

considerable improvement in the net thermal efficiency over that of a conventional combined cycle plant.

Benefits

Energy Self Sufficiency

Only a small fraction of Indian coal

is mined under-ground with most of the rest mined through strip-mining. Large reserves of coal are available at depths exceeding 300 metres that are less suitable for conventional mining technologies. This

restricts available coal resources despite large reserves in paper. Indian coal was considered ‘unmineable’ because it was under pristine forest lands, too deep, low grade or in narrow seams can be gasified thus increasing coal resource availability enormously. India also has

large deposits of lignite which is difficult to mine economically because of its low energy content. According to estimates made in 2006,

about 66 percent of low grade Indian coal at intermediate depth could be gasified underground to produce synthetic natural gas, methanol, petrol, diesel, hydrogen and also used as feedstock for fertiliser production.

Emission Reduction

High ash content in Indian coal presents an operational challenge in utilisation of domestically mined coal in surface equipment such as gasifiers and boilers. UCG has unique potential in recovering heating value from high ash coal. No coal would be transported at the surface which would also

reduce cost and local pollution footprint associated with coal transport by rail (or trucks); it would also reduce pollution associated with coal stockpiling. As conventional coal mining is eliminated with UCG,

operational costs and surface damage are reduced and mine safety is increased as accidents such as mine collapse and asphyxiation are eliminated. No surface gasification systems are needed for UCG and hence capital costs would be lower. More importantly UCG with separation and reinjection of CO

2 underground

can decouple rising electricity demand from rising green-house gas (GHG) emissions. The growing interest in hydrogen as a zero carbon energy carrier also justifies a revisit of the UCG option.

Carbon Management

Carbon capture, utilisation and storage (CCUS) have emerged as a key technology component to reduce greenhouse gases (GHGs) mainly

CO2 through geological sequestration as observed in the report by the

Intergovernmental Panel on Climate Change (IPCC). Geological carbon storage (GCS) is similar to CCUS. Storage of CO

2 in the void space made by the UCG process in the reactor zone has a number of advantages: (1) UCG creates a fairly

large cavity (in the order of 5-8 metres (m) in diameter) between wells. A single burn with 300 m spaced wells would create a

void of 6000-15000 cubic metres which can store about 8000 tonnes of CO2 (2) Production and injection wells are available for CO

2 delivery and appropriate plugging and abandonment. This will substantially reduce the cost of CCUS as the wells account

for 40-60 percent of CCUS costs (3) Physical response of coal to CO

2 may enhance sequestration. When oxygen is used for gasification, water-gas shift reactors (reacting CO with steam to produce CO

2 and H

2) to convert almost all the CO to CO

2 from which CO

2 can be readily removed by a number of available technologies.

CO2 can be stored in deep saline aquifers, depleted gas fields, active oil fields, and depleted and unmineable coal seams all of which are frequently found near coal seams chosen for UCG which makes the

UCG-CCUS package an attractive option for carbon management. As coal swells and plasticisers in the presence of CO

2, fractures and porosity may be closed quickly which will immobilise and attenuate potential CO

2 leakage.

Risks

Induced Subsidence

The void created by UCG may

cause significant deformation both in the remaining coal and surrounding rocks. Heating, quenching, water flux and potential roof and wall collapse may seriously compromise the integrity of the cavity. These are difficult to predict. In general,

the sides of the cavity move inward, the floor upward and the roof downward (subsidence). The magnitude and form of

subsidence is a function of many factors including seam depth (thickness and overburden), effective rock stiffness and yield strength.

Predictions may be inaccurate because many rocks exhibit nonlinear stress-strain behaviour.

Contamination of Groundwater

UCG operations cannot be controlled to the same extent as surface gasifiers which poses the risk on account of high temperature and pressure in the cavity. Some of the

coal in UCG may have geologic or hydrologic features that increase environmental risks to unacceptable levels. The Larger reaction zone of full-scale

UCG may create an extensive groundwater depression zone creating flow into rather than away from the combustion zone. Because

UCG is a high-temperature, high-pressure process, the production and transport of toxic organic compounds from the

burn cavity will be a consequence no matter what type of coal is gasified. Deeper UCG locations have to use higher pressure and temperature to maintain the burn zone which increases the risk of outward flow to regional groundwater. The Use of the UCG site for CCUS may

increase the mobility of many contaminants because organics are typically highly soluble in CO

2 and metals are mobilised under acidic aqueous conditions. By maintaining the

direction of groundwater flow into rather than away from the cavity the mobility of soluble contaminants could be greatly reduced.

Economics

The economics of

UCG-based power plants are not readily available as there are no UCG power plants operating in the western world and cost estimates are difficult to obtain for plants that are operating in China and Russia. In general, a

UCG-based power plant is very similar to an Integrated Gasification Combined Cycle (IGCC) power plant minus the surface gasifier. The UCG plant also needs much

smaller gas clean-up equipment because both tar and ash content in UCG based syngas is substantially lower than that obtained from a surface gasifier. These factors give UCG based power plants a significant economic

advantage over IGCC plants and Supercritical pulverised coal (SCPC) plants. Estimates put the cost of an

UCG power plant at roughly half that of an SCPC and IGCC plants and the cost of electricity generated using a UCG plant at roughly a fourth of that from an IGCC or SCPC plant.

The economics of the

UCG has major uncertainties that are likely to persist. UCG is an inherently ‘unsteady’ state process and both the flow rate and the heating value of the product gas will vary over time. Any operating plant must take this factor into account.

Many important process variables such as the rate of water influx, the distribution of reactants in the gasification zone and the growth rate of the cavity can only be estimated from measurements of temperature and product gas quality and quantity. Changes in the quantity and quality of gas produced

will have a significant impact on the economics of the project. On the other hand, the capital expenditure of UCG projects can be substantially lower than equivalent surface gasifiers because the purchase of a gasifier is not required. Operating expenses on account of coal mining, coal transport and ash management are also

substantially reduced in UCG. Even for projects that have substantial environmental monitoring and safety facilities UCG plants have maintained their economic advantages.

Overall, UCG carries strategic advantages such as the use of a domestic resource that will contribute to energy security, cost competitiveness over alternative clean technologies and low demand on scarce land resources in India. However, it also carries huge environmental and geological risks. To make the right choice for India, careful analysis of the costs and benefits of UCG through detailed pilot projects will be required.

Source: Singh, A K Underground Coal Gasification in India, Central Mining Research Institute, Dhanbad

Source: Singh, A K Underground Coal Gasification in India, Central Mining Research Institute, Dhanbad

The views expressed above belong to the author(s). ORF research and analyses now available on Telegram! Click here to access our curated content — blogs, longforms and interviews.

This article is part of the series

This article is part of the series

PREV

PREV