-

CENTRES

Progammes & Centres

Location

PDF Download

PDF Download

Arkalgud Ramaprasad, Chetan Singai, and Thant Syn, “Building a Chip Manufacturing Workforce: India’s Higher-Education Imperatives,” ORF Issue Brief No. 764, December 2024, Observer Research Foundation.

Introduction

The use of semiconductors is expanding exponentially across the world. Semiconductors are critical to national security and the economy, as well as in projecting geopolitical and geoeconomic heft. They are also critical for modern defence, enabling sophisticated weapons, surveillance technologies, and communication systems. For instance, enabling access to secure, advanced semiconductors for defence applications can help avoid the consequences of dependency on other countries and export restrictions.[1] Additionally, control over semiconductor technology has become a tool of geopolitical leverage.[2] The global semiconductor race is thus reshaping alliances, trade policies, and innovation trajectories across the world.

India, like many other countries, has embarked on a national, large-scale, long-term effort to manufacture semiconductor chips.[3] The financial outlays for the semiconductor industry is a testimony to India’s commitment to build a robust semiconductor ecosystem. At the global semiconductor supply chain meet in September 2024, Prime Minister Narendra Modi reiterated his commitment to the country’s semiconductor mission, stating, “Whether it is mobile manufacturing, electronics, or semiconductors, our focus is clear—we want to build a world that doesn’t stop or pause in times of crisis but keeps moving forward.”[4] He announced an allocation of a special research fund of INR1 trillion through the Anusandhan National Research Foundation to foster innovation in cutting-edge semiconductor technology.[5]

At the policy level, the National Policy on Electronics-2019 (NPE-2019)[a] seeks to ensure the growth of the electronics system design and manufacturing sector. NPE-2019 is aligned with the broader initiatives associated with ‘Make in India’ and ‘Digital India’, strengthening India’s position in the global electronics market.[6]

At present, India lacks a roadmap to develop the necessary workforce for semiconductor manufacturing.[7] India needs to mobilise technically qualified personnel in large numbers and provide them with competitive remuneration to succeed in its efforts to become a trusted partner in the global semiconductor supply Chain.[8] The workforce availability must align with the proposed plants’ implementation schedules and locations.[b] Additionally, the workforce will need to be provisioned with the requisite residential infrastructure, especially since many planned manufacturing sites are greenfield and far from existing manufacturing centres. This is a novel, complex, large-scale, and ambitious project. Without methodical efforts, India’s ambitions to develop a workforce is unlikely to be fulfilled. The workforce development must be systemically engineered rather than undertaking sporadic, separate efforts.

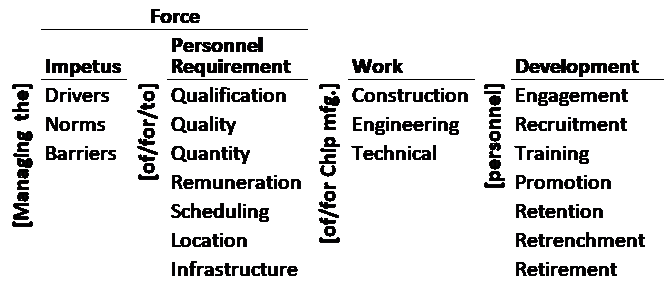

Figure 1 provides a ‘word map’ for systematic workforce development for chip manufacturing, drawing from the authors’ research and the application of such frameworks in higher education and other domains. It is the authors’ attempt at a linguistic deconstruction and organisation of the keywords associated with the phrase “workforce development”.

Figure 1: A Word-Map for Workforce Development for Chip Manufacturing in India

Source: Authors’ own

The types of work and personnel requirements are derived from existing discourse on the subject. The word-map can act as a roadmap for national private-public partnerships, enabling central, state, and local policies to channel their own as well as their stakeholders’ efforts in the coming decades. The country’s political, private, and administrative leaders and institutions must parse the potential pathways in the map to fulfil their ambitions, analyse and reinforce effective pathways, assess and redirect ineffective pathways, and experiment to discover innovative measures in formulating their blueprints. They must systematically incorporate lessons from around the globe to design their pathways for workforce development for chip manufacturing. The map must be adapted based on feedback and learnings from stakeholders and can serve as a blueprint for workforce development for chip manufacturing.

How to Read the Word-Map

The word-map is first read by columns, then combined with elements across the columns to describe the pathways for workforce development. The pathways together present the map of the challenge.

The ‘work’ component in the context of workforce for chip manufacturing comprises construction, engineering, and technical personnel with advanced skills and specialised training. Construction work includes welding, electrical work, carpentry, masonry, and other skilled trades; engineering work includes process, equipment, production control, integration, and yield engineering; and technical work includes operation, maintenance, and repair of the above engineering.[9] These global categories may be extended, refined, and localised.

The force components manage the drivers of, norms for, and barriers to fulfilling the personnel requirements for the types of work. The stages of personnel development correspond to the stages used in human resources management. The ‘force’ is a product of ‘personnel requirement’ and the ‘impetus’ on their fulfilment. The personnel requirements include educational qualification, quality of training, numerical quantity, remuneration, availability schedule, availability location, and living infrastructure. The impetuses are the drivers of fulfilment of the requirements that must be mobilised, the norms for the requirements that must be met, and the barriers to fulfilment that must be neutralised. The agents of the impetuses are individual leaders, private and public institutions, governments at various levels, and the society at large. Their agency must be mobilised, formalised, and managed systemically to channel and harmonise their effects.

The ‘development’ of personnel must follow a continuous, sustainable cycle with ongoing feedback and learning and should persist for years, if not decades. It must drive the specialised cadre of personnel through engagement with the industry, recruitment, training, promotion, retention, retrenchment, and retirement. These stages must adapt to the changes in the work, personnel requirements, and impetuses in each cycle to be aligned with the advances in the chip manufacturing technology. Finally, each cycle must adapt to technological and other changes within the country as well as around the globe. This can create a global market for these personnel, as in the case of software development personnel.

There are 378 pathways for chip manufacturing workforce development in the word-map. Each pathway is a concatenation of a word from each column with the adjacent words/phrases. The following are three pathways, with examples:

Example: The drivers of upskilling welding, electrical work, carpentry, masonry, and other skilled trades must be mobilised. Select trade schools and polytechnics must be incentivised to upgrade and revise their syllabus according to requirements, or in-house training must be planned to upskill available personnel.

Example: The norms for training operation, maintenance, and repair personnel for the many types of engineering must be established, implemented, and assessed continuously. This must be accomplished through the syllabi and curriculum of higher education institutions (especially engineering and related disciplines) and the assessment of their graduates.

Example: A career path in chip manufacturing will be a novel opportunity for a generation that views information technology as synonymous with software.[10] Future graduates and trainees must be engaged and recruited to new career paths to ensure sufficient numbers.

The blueprint for each pathway must be based on detailed analysis. India must navigate these pathways efficiently, effectively, and ethically through its system of higher education.[11] There must be a synergistic relationship between the workforce requirements and the higher education system.

Each pathway will require a set of strategies, policies, and decisions by stakeholders in higher education. The implementation of pathways must be harmonised across institutions. India’s national and state higher education policies must be harnessed to achieve its vision. A detailed analysis of the 378 pathways will be voluminous but necessary to engineer the solution systemically and systematically.

Harnessing India’s National and State Higher Education Policies

India’s semiconductor industry is poised for significant growth, offering a promising future for individuals with vocational skills. As the country aspires to become a global leader in chip manufacturing, the demand for skilled technicians, engineers, and specialists will increase exponentially. Vocational training provides a practical, efficient pathway for individuals to enter and excel in this dynamic industry. By investing in vocational education, India can build a robust, industry-ready workforce that meets the growing needs of the semiconductor sector, driving innovation and global competitiveness.

Higher education will play a key role in workforce development, especially developing the skilled workforce needed to drive India’s economic and technological growth. The development efforts must work in tandem with India’s higher education system—and not just individual institutions of excellence—to fulfil the requirements of personnel and meet the evolving demands of industries like semiconductor manufacture.[12] The National Education Policy (NEP), together with education policies being developed by many states, can provide a framework for this.[13]

The NEP 2020[14] and subsequent state-level interventions provide a strategic framework for aligning education programs with workforce development. NEP 2020 contains provisions for holistic development (life and soft skills), vocational education, skill-based learning, and research-driven innovation. It highlights the importance of science, technology, engineering, and mathematics (STEM) education, focusing on interdisciplinary learning and research.[15] Such a STEM-oriented, interdisciplinary approach will equip students with the skills required in high-tech industries like semiconductors, enabling India to cultivate a pool of professionals who are critical to the sector.

An important feature of NEP 2020 is the establishment of the National Research Foundation (NRF), designed to drive research and development (R&D) across sectors, including semiconductor technology.[16] The NRF will play a crucial role in bridging the fragmented higher education landscape by promoting research, innovation, and collaboration. It is also tasked with fostering research-led entrepreneurship through incubators and technology commercialisation programs, creating a robust ecosystem that not only nurtures interdisciplinary studies but also enhances India’s technological capabilities in critical fields like chip manufacturing.

Moreover, NEP 2020 calls for a strong industry-academia interface to ensure that educational outcomes are aligned with industry needs. This interface will be enhanced through measures such as rankings, accreditation, and performance evaluations, incentivising institutions to partner with industries. Many higher education institutions (HEIs) have already embraced this model, collaborating with industries to offer hands-on student learning experiences and skill development programmes, support cutting-edge research, and establish joint research labs. These collaborations are essential for driving innovation and ensuring that graduates are equipped with practical, industry-relevant skills.

A key element of NEP 2020 is the integration of vocational education into the mainstream education system, starting from secondary school. This reform aims to create a well-rounded, skill-oriented workforce by making vocational training a core part of both school and higher education.[17] By closing the skills gap, this approach ensures that graduates from Indian institutions are equipped to meet the demands of modern industries, including the semiconductor sector.

NEP 2020 outlines a comprehensive roadmap for transforming India’s higher education and vocational training systems, ensuring that the country is prepared to meet the demands of emerging industries like semiconductors and allied areas.

India’s Imperatives

India must act purposively and proactively to mobilise its higher education system to deliver personnel with the requisite qualifications of the right quality, in sufficient quantity, with commensurate remuneration, on schedule, at the desired locations, and with the supportive infrastructure. Correspondingly, the human resources (HR) departments of the chip manufacturing companies must specify their requirements and implement proactive plans to engage, recruit, train, promote, retain, retrench, and retire these personnel. HR departments must specify the subcategories of work for construction, engineering, and technical personnel. These specifications can drive the higher education system’s targets for its curriculum and research as well as companies’ development plans.

India’s workforce development strategy for chip manufacturing can build on the lessons from its experience in nuclear technology, space technology, information technology, and biotechnology. These sectors have a dominant Indian workforce drawn from its higher education system, supplemented by training acquired domestically and abroad. The workforce has been drawn from the diverse national, regional, and local higher education institutions. Although there were no workforce development strategies for these technologies, the accelerated schedule for chip manufacturing to respond to the global supply chain and security threats and the nature of the technology makes workforce development in this sector different and more difficult for the higher education system, necessitating a proactive, systemic, and systematic strategy.

India’s emerging national and state higher education policies must be drivers of the strategy. The norms for the curricula in the form of syllabi with learning outcomes of courses must be developed and implemented. However, there are significant barriers to their timely introduction due to factors such as institutional (university) inertia and procedural delays in the approval of these. Further, given the nature of the technology, the curriculum will require outlays for expensive laboratories, which will introduce further delay. Universities and the industry must collaborate to develop the laboratories and cut the lead time. They must also collaborate to develop a research agenda that will be essential to sustain manufacturing capability and adapt it to the global threats and opportunities in the long run.

The central and state governments of India must play a key role in addressing the challenge of workforce development for chip manufacturing. Although manufacturing facilities are planned to be set up in only a few states, the workforce pool must be national. A national committee of representatives from these governments and other stakeholders must drive the agenda. The committee must be responsible and accountable for the successful development of the workforce for chip manufacturing in synergy with India’s national education policy.

The word-map must be adopted as a common framework for all states. Within the framework, each state can choose its pathways based on its local requirements, priorities, and resources. The adoption of a common framework will help formalise and transfer knowledge, feedback, and learnings from implementation within a state, across states, and across countries. The agenda for the committee must be as follows.

Develop a comprehensive taxonomy of the types of work necessary for chip manufacturing as a foundation for managing workforce development. The types of work will determine the specification of personnel requirements and the strategy for their development. This will be central to workforce development.

Develop and maintain a dynamic list of the requirements for the different types of work. The personnel requirements will be determined by the types of work. The requirements will depend on a variety of factors. Qualification and quality requirements will depend on chip manufacturing technology; quantity by the scale of the proposed units; remuneration by the labour market and economic forces, both local and national; scheduling by the plant implementation schedule; location by the plant location; and infrastructure by the conditions at the plant location and its vicinity.

Systematically analyse the drivers of, norms for, and barriers to fulfilling the requirements. The locus of the impetus may be the higher education institution, the company, the government, or the environment. Such an analysis will help design strategies for the three entities to harness the drivers, establish the norms, and overcome the barriers. Managing the impetus will require local interventions in the policies and processes of the institutions.

The strategy for each phase of development will depend on the type of work, the personnel requirements for the work, and the impetus for fulfilling the requirements. Generic, broad strategies may be adequate for some combinations of these, while specialised, targeted strategies will be necessary for a few. Development will require a spectrum of global/local, generic/specialised, and broad/narrow strategies.

Conclusion

Workforce development for chip manufacturing requires a roadmap. The source of the workforce is likely to be very selectively global, significantly national, and primarily regional, from the state in which the plant is located as well as neighbouring states. A majority of the Indian workforce is likely to come from public higher education institutions across tiers.

The government at the Centre and the governments in the state in which the plants are located and in neighbouring states must cooperate and collaborate to continuously mobilise the necessary workforce. Therefore, a clear, concise, and comprehensive framework is required to negotiate the pathways to meet the challenge. This framework can be used to manage the workforce development locally, nationally, and globally.

Endnotes

[a] The NPE-2019, Ministry of Electronics and Information Technology (MeitY), Government of India. The Policy envisions positioning India as a hub for Electronics System Design and Manufacturing (ESDM) by encouraging and driving capabilities in the country for developing core components, including chipsets, and creating an enabling environment for the industry to compete globally. The NPE-2019 is an updated version of the earlier NPE-2012 which focused on scaling domestic manufacturing, fostering innovation, and improving India's competitiveness in electronics production.

[b] At present, plants are being planned in Gujarat and Assam, and future plants are being contemplated in Maharashtra and Karnataka. See: https://indianexpress.com/article/business/karnataka-calls-for-centres-fiscal-support-to-boost-chip-projects-9421643/; https://economictimes.indiatimes.com/industry/cons-products/electronics/maharashtra-says-tower-adani-to-set-up-10-billion-semiconductor-unit/articleshow/113104745.cms

[1] Airland Subcommittee, United States Senate, National Security Aspects of the Global Migration of the U.S. Semiconductor Industry, by Joseph I. Lieberman, Washington, D.C., June 2003, https://ece-research.unm.edu/jimp/HOST/govt_reports/liberman_semiconductor.pdf.

[2] Yongshin Kim and Sungho Rho, “The US–China Chip War, Economy–Security Nexus, and Asia,” Journal of Chinese Political Science 29, no. 3 (2024): 433–60, https://doi.org/10.1007/s11366-024-09881-7.

[3] Patricia Cohen and River Akira Davis, “Japan Tries to Reclaim Its Clout as a Global Tech Leader,” The New York Times, September 6, 2024, https://www.nytimes.com/2024/09/06/business/economy/japan-industrial-policy-rapidus.html; Melissa Cyrill and Yashoda Kapur, “Semiconductor Industry in India: Incentives and Key Players,” India Briefing News, July 17, 2024, https://www.india-briefing.com/news/setting-up-a-semiconductor-fabrication-plant-in-india-what-foreign-investors-should-know-22009.html/; United States Congress, H.R.4346 CHIPS and Science Act, by Tim Ryan, Washington D.C., https://www.congress.gov/bill/117th-congress/house-bill/4346; Samuel K. Moore, “India Injects $15 Billion Into Semiconductors,” IEEE Spectrum, March 6, 2024, https://spectrum.ieee.org/indian-semiconductor-manufacturing; Archana Rao, “India’s Semiconductor Sector: Three New Plants Get Approved,” India Briefing News, March 13, 2024, https://www.india-briefing.com/news/indias-semiconductor-sector-welcomes-three-new-manufacturing-units-31434.html/.

[4] Prime Minister’s Office, Government of India, https://pib.gov.in/Pressreleaseshare.aspx?PRID=2053675, 2024.

[5] Prime Minister’s Office, Government of India.

[6] Ministry of Electronics and IT, Government of India, https://pib.gov.in/Pressreleaseshare.aspx?PRID=1565287, 2019.

[7] Brendan Jay et al., New Tactics for New Talent: Closing Us Semiconductor Labor Gaps, McKinsey & Company, May 2024, https://www.mckinsey.com/industries/semiconductors/our-insights/how-semiconductor-companies-can-fill-the-expanding-talent-gap.

[8] Konark Bhandari, Is India ‘Ready’ for Semiconductor Manufacturing?, Carnegie Endowment for International Peace, May 2023, https://carnegieendowment.org/research/2023/05/is-india-ready-for-semiconductor-manufacturing; Rimjhim Singh, “India’s Chip Industry to Face Shortage of 300,000 Professionals by 2027,” Business Standard, June 11, 2024, https://www.business-standard.com/industry/news/india-s-chip-industry-to-face-shortage-of-300-000-professionals-by-2027-124061100186_1.html; Nidhi Singhal, “Here’s How India Can Fill the Semiconductor Talent Gap for the World,” Business Today, July 28, 2023, https://www.businesstoday.in/technology/news/story/heres-how-india-can-fill-the-semiconductor-talent-gap-for-the-world-391665-2023-07-28.

[9] Jay et al., “New Tactics for New Talent: Closing Us Semiconductor Labor Gaps.”

[10] Anurag Awasthi, Upskilling the Chip Industry: Transforming Human Resource into Human Capital, Observer Research Foundation, September 2022, https://www.orfonline.org/expert-speak/upskilling-the-chip-industry.

[11] Arkalgud Ramaprasad et al., “India’s National Higher Education Policies Since Independence: An Ontological Analysis,” Journal of Educational Planning and Administration 30, no. 1 (2016): 5–24; Arkalgud Ramaprasad, “Envisioning a World-Class University System for India,” International Journal of Technology Management & Sustainable Development 10, no. 1 (2011): 45–54, https://doi.org/10.1386/tmsd.10.1.45_1.

[12] Ramaprasad, “Envisioning a World-Class University System for India”; Ramaprasad et al., “India’s National Higher Education Policies Since Independence: An Ontological Analysis.”

[13] Government of India, Ministry of Education, National Education Policy 2020 (New Delhi, India: Government of India, 2019), https://www.education.gov.in/sites/upload_files/mhrd/files/NEP_Final_English.pdf.

[14] Government of India, Ministry of Education, National Education Policy 2020.

[15] Nirmala Sahu and Harekrushna Behera, “National Education Policy 2020: A Historical Perspective,” International Journal for Research in Applied Science and Engineering Technology 10, no. 6 (2022): 3767–73, https://doi.org/10.22214/ijraset.2022.44872.

[16] Ministry of Science & Technology, Government of India, https://pib.gov.in/Pressreleaseshare.aspx?PRID=1935895, 2023.

[17] Ministry of Education, Government of India, https://pib.gov.in/Pressreleaseshare.aspx?PRID=1885528, 2022.

The views expressed above belong to the author(s). ORF research and analyses now available on Telegram! Click here to access our curated content — blogs, longforms and interviews.

Arkalgud Ramaprasad is Professor Emeritus, Information and Decision Sciences, University of Illinois. ...

Read More +

Chetan Singai is Professor and Dean, School of Law, Governance and Public Policy, Chanakya University, Bengaluru. ...

Read More +

Thant Syn is Associate Professor of Information Systems, Analytics, and Supply Chain, Florida Gulf Coast University, Florida. ...

Read More +