This article is part of the series — Raisina Files 2021.

Materials science is one of the most influential innovation moats for sustainable and resilient socioeconomic growth. India’s upward trajectory towards a middle-income economy started with economic liberalisation in 1991 at a Gross Domestic Product (GDP) of US$ 275 billion. Growing at roughly 8 percent annually in US dollar terms, India surpassed the UK and France in 2019 to join the top five global economies in nominal GDP terms. It is the only economy with the potential to join the US$ 10 trillion economy club after the US and China, due to favourable tailwinds in demographics, consumption and technological capabilities.

India has to achieve this feat by providing sustainable development and growth opportunities to its 1.38 billion citizens. Demand for clean and efficient energy, sustainable mobility, cutting-edge healthcare, urban infrastructure, potable water and other amenities will rise exponentially as India’s population stabilises and more people join the middle class. These are economic pillars that are integral to core government functions. In a post-COVID-19 macro-environment, most of these functions may also be elevated to the status of national security concerns.

India is the only economy with the potential to join the US$ 10 trillion economy club after the US and China, due to favourable tailwinds in demographics, consumption and technological capabilities.

Innovation in materials science can support the fundamentals of fulfilling these core government functions:

• Water and sewage treatment: Materials and biosciences are indispensable to finding novel energy-efficient methods to treat the increasing amounts of human and industrial waste, toxic effluents, heavy metals, microorganism, and contaminants in freshwater systems. Research in nanomaterials, adsorbates and composite materials, that can serve in potable water generation, needs to be a sustained national priority.

• Health and pharmaceuticals: Bio- and materials sciences are combining — in innumerable ways — to push the frontiers of product and process development in health and pharmaceuticals. The ability of materials science principles to expand the scope of therapeutic drugs, vaccine delivery and diagnostic methods via novel microscopic and nanoscopic pathways is widely recognised. It also enhances candidates for biomaterials that can interface with organic body parts like in orthopaedics and can fundamentally improve the quality of life for amputees and the disabled. Materials innovation can also provide solutions to systemic challenges like wound healing and non-invasive continuous monitoring that become crucial when dealing with large populations that are living longer and require long-term medical and hospice care.

• Infrastructure building materials: As the demand for high-capacity and quality infrastructure ramps up, it is crucial to engineer lighter, more durable and sustainable building materials. Next-generation smart materials like self-healing and self-luminous concrete, 3D graphene, aerographite and hydroceramics, to name a few, are critical to maintaining low per-capita energy and raw materials consumption while serving the surging demand for modern infrastructure in this growing economy.

• Manufacturing and processing technology: As the indigenous production of goods ramps up, it is essential to invest in next-generation manufacturing materials like engineered polymers, advanced composites and hybrids, and metals and alloys with specific properties, such as thermal resistance, energy efficiency and reduced carbon intensity. The use of new materials and composites in production-line components can help cut costs, increase service life, reduce downtime and increase productivity. Further, sensing and characterisation technologies to prevent manufacturing defects and the use of smart materials and data analytics to minimise inefficiencies will require significant investment in materials science research.

• Energy and renewables: India’s focus on energy and renewables is prudent to reduce both the emission burden and dependence on foreign economies for fossil fuels. Increasing energy harvesting efficiency from solar, wind, and water, and introducing lower-cost materials that ultimately make technologies viable for mass deployment hinges on identifying new materials and mechanisms. New battery chemistries will enhance energy storage at the individual- and grid-levels, and enable higher renewable energy utilisation. Other material types like piezo-electrics, 2D materials and polymers are encouraging candidates to unlock new energy generation and storage modes. There are also promising catalysis-based energy generation methods like photocatalysis and electrocatalysis, which currently cannot be deployed large-scale due to inefficient catalyst candidates. Materials innovation can change this.

• Mobility: Two critical factors in increasing the efficiency of mobility options while reducing the pollution burden are moving away from fossil fuels and engineering lightweight carriages. Both need significant materials innovation to deliver a steady user experience continually. Reducing fossil fuel dependence requires innovation in batteries, magnets and magnetic levitation technologies, fuel cells and other compact energy modes. Improving battery technology involves innovation in the current standard lithium-ion and future candidates like metal-air, metal-ion and solid-state batteries. Hydrogen and solid-oxide fuel cells also show promise to replace conventional internal combustion engine-based transport. Apart from these new modes, lightweight design also necessitates innovation in hybrid materials, composites and alloys.

• Food and agriculture: The biggest problem in food and agri-supply chains is often not production but distribution and supply inefficiencies, leading to large-scale spoilage and wastage. Materials innovation can make cold chains more energy-efficient, increase the shelf life of produce and decrease microbial action at high temperatures. Food packaging is amongst the largest contributors to consumer-generated solid waste, and investment in bio-degradable materials will improve the sustainability of the food supply chain in the country.

• Defence: A country’s defence network needs constant upgrades to actively combat new security threats and maintain operational effectiveness. Lightweight but durable materials, weather-resistant clothing, self-healing materials, biomimetic design, aerofoils and cyber protection all become critical to soldiers’ and armies’ abilities to survive in extreme temperatures and enforce border integrity. Autonomous bipedal and quadrupedal robots and unmanned aerial vehicles are being integrated into core defence and military strategies by many countries, and employ a significant materials innovation component. Advanced-composites are critical to deploying large-scale military strategies using materials innovation.

Apart from the core economic pillars of governance, frontier technologies that are equally important to maintaining economic security also require significant materials innovation:

• Computing: As human lives become intertwined with the digital, computing capabilities that unlock faster transmission, efficient data storage and quicker processing are becoming vital to economic operations. Materials innovation drives computing beyond silicon’s capabilities and towards the intensive requirements of artificial intelligence, machine learning, and quantum and neuromorphic computing. New materials that enable graphene-based microchips, organics-based molecular electronics, and DNA data storage look promising and require significant investment in research and development (R&D). These new modes of computing run on high amounts of energy and require adequate cooling, which also needs next-generation materials to enable useful and hybrid heat transfer modes.

• Space: Space is an essential economic frontier for communications, terraforming, mining new materials, and extended national security operations. There is always a need for lightweight materials to reduce operational costs and resource utilisation in space while providing multifunctional capabilities like radiation shielding, stability in extreme temperatures, specific electro-thermal-mechanical properties and self-healing. Shape memory alloys and polymers will fuel the engineering of smart wings (like birds) that can optimise flight patterns, not just in space flight but ordinary air travel as well.

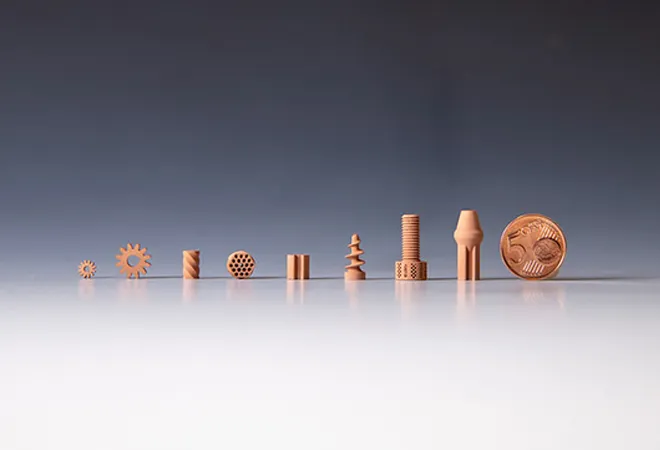

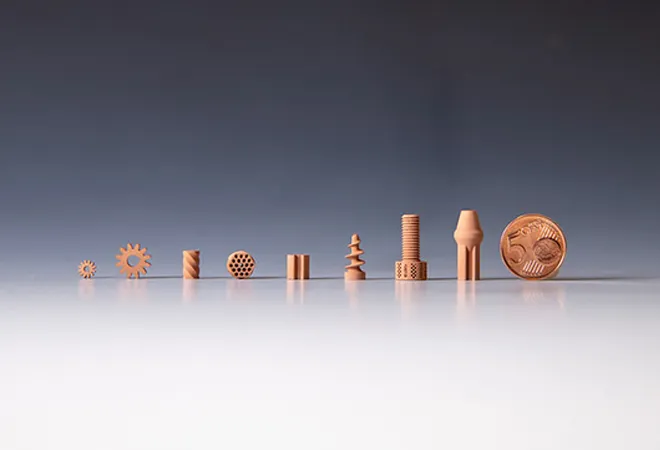

• 3D printing: 3D printing, or additive manufacturing, enables decentralised and customisable manufacturing, and is increasingly unlocking newer economic avenues. Customisable prosthetics, implants and organ tissue like liver and corneas are driving individualised healthcare. In manufacturing too, 3D printing allows advantages like on-demand production and the design and production of new materials and composites with specific properties that cannot be obtained in bulk manufacturing. Metal 3D printers are currently a global objective as this capability will enable waves of innovative additive manufacturing and reduce or eliminate the many problems associated with subtractive manufacturing. Further, multi-materials 3D printers that can combine different materials to produce hybrids with specific properties can accelerate many economic sectors like construction and manufacturing.

• Robotics: Robotics is a crucial field as it enhances human ability to build and maintain large economic systems multifold — infrastructure, natural environments, space fleets, crop harvesting, and several other applications have embraced automation through robotics. Robotics is already revolutionising the fields of surgery and medical delivery. It will soon pave the way for deployable nanobots in the human body to identify diseased cells and deliver targeted therapeutics. Robots will become ubiquitous and require materials innovation in low-density structural components, fast electronics, sensors, bio-compatible embedded systems and many other streams.

Undoubtedly, the nation(s) that develop the specialisation, technology, design and intellectual property (IP) in materials innovation will lead the world economically and command favourable economic and trade agreements. India must invest in attaining that position with a 50-year outlook.

Leading economies

India is active in materials science innovation; however, it pales in comparison to the investments leading economies like the US, China, Germany and Japan have made in frontier materials science innovation.

The US spends about 3 percent of its US$ 21 trillion economy on innovation and research, while China spends 2 percent (of US$ 15 trillion), Japan spends 3.6 percent (of US$ 5 trillion), and Germany spends 3 percent (of US$ 3.9 trillion). All four economies operate on advanced infrastructure, technology and manufacturing, which incorporate significant materials innovation. In contrast, India spends less than 1 percent (of nearly US$ 3 trillion) on innovation R&D. Further, the leading economies have developed large, specialised workforces for research — on a per million population basis, the US has 4,500 researchers; China 1,000; Japan 5,500; and Germany 4,500. India has only 100 per million population, a direct consequence of brain drain and the dearth of major government research grant programmes for universities and research laboratories.

India is active in materials science innovation; however, it pales in comparison to the investments leading economies like the US, China, Germany and Japan have made in frontier materials science innovation.

Materials innovation is a core component of these countries’ innovation spending. The US has entrenched research funding organisations like the Defence Advanced Research Projects Agency (DARPA) and the National Science Foundation (NSF). DARPA was founded in 1958, and materials science has been a core driver since 1960. Key innovations out of the DARPA ecosystem, like radar evasion, GPS, aeronautics and drone technology, have become ubiquitous today and stem from their focus on new materials. Research under the DARPA programme often results in dual-use technologies, by the military and the government to provide advanced services to the American citizenry. In 2020, DARPA’s funding amounted to US$ 3.46 billion, nearly all of which is directed towards scientific and technological development.Similarly, the NSF offers sustained grants to top universities to advance cutting-edge materials science research. Foundational programmes like DARPA and NSF ensured that the US remained an undisputed leader in materials science research for decades.

The US also launched the Materials Genome Initiative (MGI), a “federal multi-agency initiative for discovering, manufacturing, and deploying advanced materials twice as fast and at a fraction of the cost compared to traditional methods” by adopting informatics, machine learning and multivariate data analysis. Discoveries under MGI are fuelling the rapid deployment of advanced materials in the US’s design and production chains.

Meanwhile, China has invested heavily in scientific research and is fast catching up with the US. The National Natural Science Foundation of China (NSFC) had a budget of US$ 3.9 billion in 2016 and accounted for a third of China’s research funding. Materials science is one of eight main pillars funded by NSFC’s Open Application Fund. China has also developed a cluster model for funnelling research into productisation with the National High-tech Zones, responsible for developing the “world’s first U disk, China’s first supercomputer, and its first AI chip,” among other innovations. These clusters concentrate innovation-driven industries and benefit from high-speed infrastructure, talent concentration, and special tax incentives to attract investment.

Materials science is not tracked as a unified field, but several fields that incorporate it are witnessing steady growth rates in the number of patents published.

A Thomson Reuters report tracked publications in materials science and technology placing China in the first position, followed by the US, with India in the sixth position. India published roughly one-fourth and one-third that of China and the US, respectively, with a significantly lower impact score compared to the US and the European Union.

The World Intellectual Property Indicators 2020 report shows China holds 43.4 percent of worldwide patent applications, followed by the US at 19.3 percent and Japan at 9.6 percent. India is in the seventh position, but with a healthy annual growth rate of 7.1 percent. Materials science is not tracked as a unified field, but several fields that incorporate it are witnessing steady growth rates in the number of patents published.

With the establishment of the National Research Foundation (NRF) and an initial five-year outlay of INR 500 billion (US$ 6.85 billion) in the 2020-21 Union Budget, India is now prioritising scientific research. Funding materials science research that feeds into core and frontier economic pillars must become a fundamental component of the NRF.

A 50-year vision

It is impractical for a large and accelerating economy like India to remain dependent on other countries for technology designs integral to every central economic pillar. The country has to own the research, development, IP, design, and production of all these critical components and technologies. For this, it is vital for India to develop innovation engines with a 20-year to 50-year vision of dominating the knowledge economy and using that competitive advantage to become a technology providerand exporter.

The Indian government must focus on building vertically integrated innovation-to-productisation ecosystems to facilitate this vision:

• Deep funding grant systems: India must set up comprehensive grant systems to stimulate R&D for all the primary materials science-feeder economic pillars. Non-lapsable grants and follow-on funding for promising ideas and prototypes have been highly successful in the US’s DARPA and NSF funding systems. India’s NRF must strive to extend the depth of funding, similarly, and aggressively support dual-use R&D.

• University funding: Universities hold the greatest critical mass of talent and can be mobilised towards national research goals with adequate funding. Advanced economies have successfully harnessed this intellectual might by allocating a significant amount of grant funding to professors and research students at universities. Institutions also require adequate funding to build world-class laboratories and stay updated with the latest technologies so their researchers have continuity of access to the world’s best tools.

• Research facilities: Apart from universities, government and private research facilities can be hotbeds of innovation. For example, the US has a string of top-notch national laboratories, like Sandia and Lawrence Livermore, established during the Second World War and maintained and upgraded continuously to support their research and innovation output. All those laboratories contain a primary materials science component within their research wings.

• Tax incentives to corporates: The private sector can be encouraged to partner with the government in India’s mission to become a technology leader through tax incentives. Domestic corporates developing indigenous technology that can feed into the economic pillars can utilise the tax incentives to channel funding into R&D.

• Innovation hubs: Academic research must go hand in hand with comprehensive productisation and go-to-market pathways to successfully deploy technologies. Innovation hubs have proven very useful in providing these ecosystems. Domestic innovation hubs like the Centre for Cellular and Molecular Platforms have helped scientist-entrepreneurs and academic researchers take their technologies to the market. India must establish innovation hubs for every economic vertical and deepen existing hubs’ capacity and capability to provide an innovation backbone.

• D scholarships: India has lost many bright minds to European countries and the US due to a lack of scholarships and world-class facilities. In 2018-19, only 169,170 students were enrolled in Ph.D programmes across the country, amounting to less than 0.5 percent of total enrolment in India’s higher education system. India must utilise the NRF outlay to exponentially increase the number of Ph.D positions, especially in core materials science fields, so academic research can be channelled towards economic growth.

• Government research organisations: India has some prominent government research organisations that are developing world-class technologies, such as the Indian Space Research Organisation and Defence Research and Development Organisation. These organisations can appoint dedicated chairs for materials science research to focus on key innovation that can result in practical dual-use technologies. The government can pursue targeted IP portfolios that benefit the Indian citizenry while furthering national economic interests.

• Startup clusters and scale-up spaces: Apart from academic and research institutions and corporates, startups are crucial to further push the technological frontier. The number of deep science startups in several verticals, including materials science, biosciences and computing, is steadily growing in India. Ample provision of early-stage government funding and assured continuity of follow-on funding will ensure that startups do not have to suspend operations while raising capital and can quickly ramp up their activities. Further, materials science innovation requires scale-up spaces as activities ramp up from ideation to productisation. Instead of startups wasting precious time procuring land and other amenities, the government’s provision of grow-out space will speed the go-to-market process, much like China’s National High-tech Zone model.

• Production chains: As COVID-19 has shown, it is not viable to remain dependent on China or any other external player to supply essential goods. With this sentiment, India’s 2021–22 Union Budget lays down production linked incentive (PLI) schemes for 13 manufacturing sectors, all of which will benefit from core IP generation within the country. As India’s IP base expands, it must be linked with PLI schemes and supply chain networks to produce and distribute the products across the country efficiently.

• Sourcing and upstream supply chains: Innovation predicated on materials science depends on sourcing of specific metals and rocks; for example, rare earth metals, of which China controls 90 percent of global production and supply. While ramping up innovation engines, India must also ensure sourcing for these technological designs. India recently started creating government-to-government dispensations to secure critical mineral supply chains in South America, including lithium. These forward-sourcing strategies must be part of the innovation-ecosystem support framework.

Conclusion

India undoubtedly needs strong innovation engines as part of its core strategy to scale to a US$ 5 trillion economy in the next few years and US$ 10 trillion economy in this decade. An in-depth focus on materials science must be part of this innovation strategy to fuel core economic sectors and frontier sectors that will drive the next economic growth era. When linked to productisation and manufacturing, these innovation engines will fuel economic growth and create an unprecedented wave of employment prospects for India’s 1.38 billion-strong population. World-class technology will always find global markets to export to and create favourable trade positions for India to capitalise. Studying the US and China’s ecosystems demonstrates that this is a 20-year to 50-year outlook to reap substantial and long-term returns, and the time to start is now. Investing in materials is akin to investing in India’s future.

Joe Myers, “India Is Now the World's 5th Largest Economy,” World Economic Forum, 19 February 2020.

M.Somasekhar, “India Ranked 6th Globally in Materials Science Research,” The Hindu Business Line, 11 August 2011.

UNESCO, “How Much Does Your Country Invest in R&D?,” UNESCO UIS.

“How Much Does Your Country Invest in R&D?”

“How Much Does Your Country Invest in R&D?”

“A Selected History of DARPA Innovation,” DARPA Sixty Years, DARPA.

Marcy E. Gallo, “Defense Advanced Research Projects Agency: Overview and Issues for Congress,” Congressional Research Service, 17 March 2020.

Materials Research Science and Engineering Centers, National Science Foundation.

Materials Genome Initiative, US Government.

Albert G.Z. Hu, “Public Funding and the Ascent of Chinese Science: Evidence from the National Natural Science Foundation of China,” Research Policy Vol. 49 Issue 5, Elsevier, in Science Direct.

“China's high-tech industrial zones, a unique growth engine,” PR Newswire, 18 November 2020.

Jonathan Adams and David Pendlebury, Global Research Report Materials Science and Technology, Thomson Reuters Evidence, 2011.

WIPO, World Intellectual Property Indicators 2020, Geneva, World Intellectual Property Organization, 2020.

National Research Foundation, Office of the Principal Scientific Adviser to the Government of India.

National Laboratories, US Department of Energy.

Vanita Srivastava, “Nearly 85% Rise in Brain Drain from India to US in 10 Years,” Hindustan Times, 1 October 2015.

TV Mohandas Pai and Nisha Holla, “Seven Trends In Indian Higher Education Every Indian Must Know,” Swarajya Magazine, 1 December 2019.

Nisha Holla and Team YourStory, “Deep Science for Deep Impact,” YourStory.

Nisha Holla and Taslimarif Saiyed, “Essential for India to Develop an Innovation Ecosystem That Can Generate Multi-Million Dollar Businesses,” The Financial Express, 8 November 2019.

Aditi Agarwal, “Budget 2021: Mobile Manufacturing Gets A Make In India Push,” Forbes India, 2 February 2021.

Aylin Woodward, “China Could Restrict Its Export of Rare-Earth Metals as a Trade-War Tactic. Here's What They Are and Why They're so Crucial,” Business Insider India, 4 June 2019.

Rakhi Mazumdar, “India to Acquire Reserves of Strategic Minerals to Power the Country's Move into EVs,” The Economic Times, 30 May 2019.

The views expressed above belong to the author(s). ORF research and analyses now available on Telegram! Click here to access our curated content — blogs, longforms and interviews.

PREV

PREV