-

CENTRES

Progammes & Centres

Location

We are living in a complex world wherein intra-country and inter-country inequality has become a norm, which inadvertently affects labor markets and global poverty. Early industrialized countries had the advantage of entering the trajectory of economic growth sooner than their counterparts, which created a gap between developed and developing countries. Today in the wake of fourth industrial revolution, the technological advancements are perpetuating this difference. Specifically, developed economies seem to be better placed to improve their productivity with the help of advanced technology. On the other hand, developing countries appear to lack capabilities to make optimum use of emerging technologies. Hence, questions of technological innovations and their adoption for industrial production have become crucial in developing countries like India.

Robert Baldwin explains that from 1970’s western economies explored availability of ‘cheap labor’ in developing countries to lower the cost of production and to maximize their profits. The revolution in transport technology and ICT made it possible to disperse the production clusters all over the world (Baldwin, 2013). This process boosted manufacturing sector in emerging economies and created better employment scenario. As per one estimate, US outsourced 3.2 million jobs to China from 2001 to 2013, out of which 2.4 million were found to be in manufacturing sector (Kimball and Scott, 2014). Thus, post 1980s countries like South Korea, Taiwan, China and India were benefitted due to availability of cheap labor. There was also a significant rise in their production capabilities. However, this process ended up being ephemeral.

D. Rodrik, argues that developing countries lack comparative advantage in manufacturing sector as their technology is inadequate to meet the demands of manufacturing sector. This implies that, when advanced countries reduce their costs of production through better technology; industries in developing countries will end up becoming unviable. This would lead to ‘pre-mature’ deindustrialization. Thus, he points out that industrialization is not yielding long term economic growth in the developing countries, the way it had yielded in developed nations.

Technologies such as AI/Blockchain/3D printing are boosting productivity by a substantial margin and transforming life, business and global economy. Hence, these techniques are often referred to as ‘disruptive technology’. For instance, today, robotic automation is influencing cost-efficiency in all sectors including manufacturing, transport, hospitality and agriculture. No wonder, many middle-end jobs, which require basic skills and repetitive tasks are being replaced by ‘automation’. Recently iPhone supplier company Foxconn replaced 60000 workers with robotic automation in one of the factories in China (Zaleski, 2017).

Similarly, artificial intelligence (AI), combined with machine learning & deep learning, mimics human brain and builds self-correcting capabilities in robots. When fed with large scale data, AI-enabled units self-learn/adapt to perform complex functions. For example, robots from Fetch Robotics can control almost every activity of inventory management in a warehouse. Moreover, robots like Amelia (by IPsoft) can process language, read manuals and control remote operations with its unique problem-solving abilities. Thus, with the help of smart robots, it is possible to secure large scale production at cheaper rate without involving human capital. It thus rules out the necessity of cheap labor in the production units of large global companies. Hence, AI is transforming the economies especially in developed world. As per one such estimate, US economy would see annual GDP growth rate of 4.6% in 2035 due to adoption of AI enabled system (Purdy and Daugherty, 2016). As against this, emerging countries (barring China) lack sufficient capabilities of highly functional robot manufacturing (Zaleski, 2017). No wonder, their participation in future production processes is at risk.

Blockchain and 3D printing technologies are also improving the cost effectiveness of manufacturing sector in developed countries. Blockchain, a ‘distributed’ ledger, decentralizes the data validation system and reduces various transaction costs incurred by several intermediaries, who certify authenticity of transactions. This has revolutionized the manufacturing sector by reducing costs of inventory management, supply chain management, patent security etc (Greenfield, 2017).

Similarly, 3D printing/additive-manufacturing techniques help in transforming digital prototypes into a real object by layering material through programmed commands. Initially this technology was limited to the niche and expensive products such as medical implant. However, it has now intruded in the manufacturing of products of daily use, such as retail goods and food items. Thus, it not only reduces several steps in the production and distribution systems, but it also makes entire manufacturing process more dispersed and customized. It reduces necessity of warehouses; transportation / shipping and distribution systems and it affects entire lifecycle of global supply chains (Lim and Nair, 2017).

To enable both these technologies realize their full potential, there is a requirement of infrastructure in the form of interconnected computers with robust network facilities (Pisa and Juden, 2017). Moreover, blockchain requires huge source of uninterrupted power supply and large processing units throughout the network to achieve decentralized data management (Graglia Michel et al., 2017). All these pre-conditions are prominently present in developed world. Thus, the benefits of widespread implementation of blockchain and 3D printing technologies are expected to be appropriated by developed countries.

All disruptive technologies tend to reduce production costs in developed countries. Hence, large companies are bringing production units back to developed countries. As per the estimate, during last five years, many jobs flew back to USA from emerging economies. Companies like Nike are also preferring developed countries over poor countries for new production units. On the other hand, developing countries are suffering with ‘pre-mature deindustrialization’.

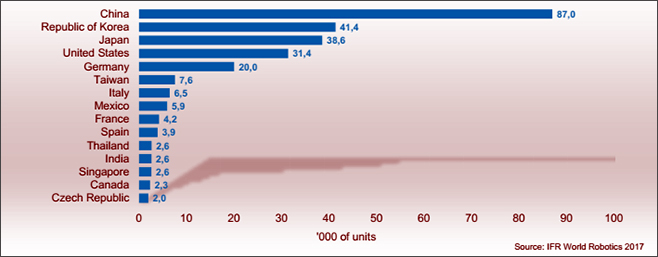

The impacts of adopting advanced technology in a globally integrated world are bound to be far reaching and significant in nature especially when only few countries are gaining from it. Considering this fact, developing countries need a long-term vision to achieve growth in manufacturing sector and to boost local economies. They must invest huge energy in understanding a disruptive technology and changing pattern of production systems. As indicated in figure 3, China is striving to position itself as a leader of innovation in robotics. It’s ‘Made in 2025’ plan aims to outpace countries like US and Germany at in-house robot sophistication with the help of massive credit sources, infrastructural facilities and tax breaks (Zaleski, 2017). However, most of other developing countries lag far behind in attuning their policies towards changing demands of technologies.

Figure 3: Estimated worldwide annual supply of robots, 15 largest markets – 2016

(International Federation of Robotics, 2017)

(International Federation of Robotics, 2017)

Hallward-Driemeier and Nayyar put forward 3-C model for developing countries to promote manufacturing sector in the changed context. Accordingly, emerging economies must reconfigure their respective competitiveness. Disruptive technologies would affect several sectors differentially at different points of time. For instance, AI technology makes cheap labor redundant in automobile industry, but abundant labor is still a necessity in sectors like textile or commodity processing (oil and gas). Thus, nations can select sector-specific strategies to survive in the global economy.

Further, emerging economies can promote innovative business models, better protection of intellectual capital and can foster partnerships with leading global innovators to improve the capabilities. For instance, Chinese company Midea struck US $4.6 billion deal to acquire German based Kuka AG which has strong R&D base for robot manufacturing for automotive sector (Zaleski, 2017). Moreover, they can invest in promoting relevant skill-sets amongst youth and adult labor force. In this regard, experiments in developed countries are worth emulating. United Kingdom, Spain and France are extensively building skills such as coding, critical thinking and problem solving to make adult employees suitable for new production systems. In addition to such innovative skill development programme, developing nations can also invest in STEM education facilities to improve capabilities of future employees.

Policy makers of developing economies can also explore connectedness between several sectors to ensure that manufacturing remains in growth zone. They must formulate policies to strengthen forward and backward linkages of manufacturing sectors with the trade, agriculture and service sectors. Fourth industrial revolution in developed countries would negatively affect export from emerging economies. Hence, in the changed circumstances boosting domestic economy through interconnected flourishing sectors is crucial for developing economies. Overall, with 3-C strategy, emerging countries can ensure better preparedness to tackle the challenges of disruptive technologies (Hallward-Driemeier and Nayyar, 2017, pp 169-208).

The views expressed above belong to the author(s). ORF research and analyses now available on Telegram! Click here to access our curated content — blogs, longforms and interviews.

Rohan is an engineer turned social scientist. He is a recent graduate from Institute of Development Studies (IDS UK) wherein he has analysed technology-led and ...

Read More +