This article is part of the series Comprehensive Energy Monitor : India and the World

Basics

Direct air carbon capture and storage (DACCS) technologies extract carbon dioxide (CO

2) directly from the atmosphere and store it permanently in deep geological formations or use it for food processing and synthetic fuel production. When CO

2 is stored underground it achieves negative emissions but when it is used in synthetic fuel production CO

2 is re-emitted into the atmosphere when the fuel is burnt but there is reduction in overall CO

2 emission.

Liquid air capture technologies are based on using water solutions containing hydroxide sorbents with a strong affinity for CO

2, such as sodium hydroxide, calcium hydroxide, and potassium hydroxide that remove CO

2 from air and return the rest of the air to the atmosphere. Solid direct air capture technologies, currently at the research stage, use solid sorbent filters such as amine materials bonded to a porous solid support. A wider range of solid sorbents such as ionic membranes, zeolites, solid oxides that chemically bind with CO

2 are being investigated. When the filters are heated, they release the concentrated CO

2, which can be captured for storage or use. Both solid and liquid capture technologies could be fuelled by renewable energy sources, such as geothermal, solar, and wind, while solid direct air capture could be powered by recovering waste heat, which would reduce lifecycle emissions considerably.

Solid direct air capture technologies, currently at the research stage, use solid sorbent filters such as amine materials bonded to a porous solid support. A wider range of solid sorbents such as ionic membranes, zeolites, solid oxides that chemically bind with CO2 are being investigated.

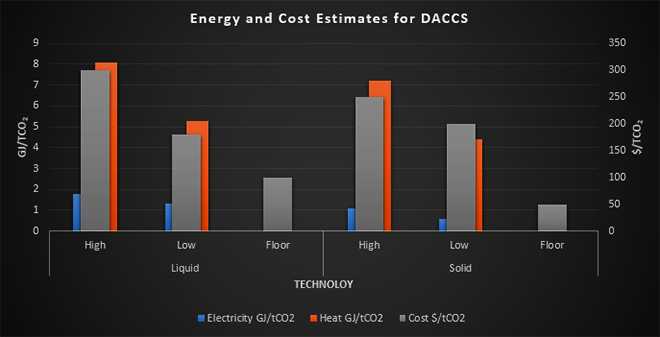

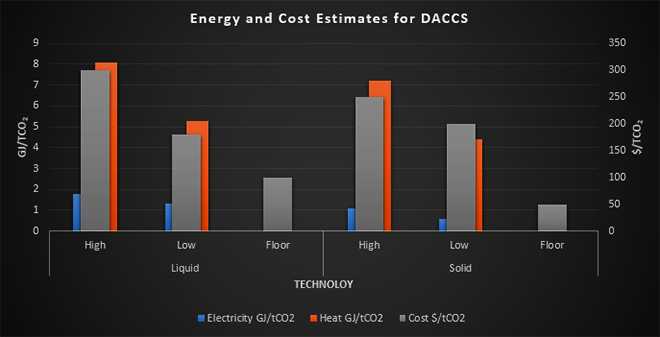

The CO

2 in the atmosphere is much more dilute than the flue gas from a power station or a cement plant. This contributes to the higher energy needs and costs for direct air capture relative to other CO

2 capture technologies and applications. CO

2 needs to be compressed at a very high pressure to be injected into geological formations. This increases both the capital cost of the plant—due to the requirement for additional equipment such as a compressor—and the operating costs—to run the compressor. If the plant is located close to storage or utilisation site, the need for long-distance CO

2 transport is eliminated thus reducing cost.

Progress

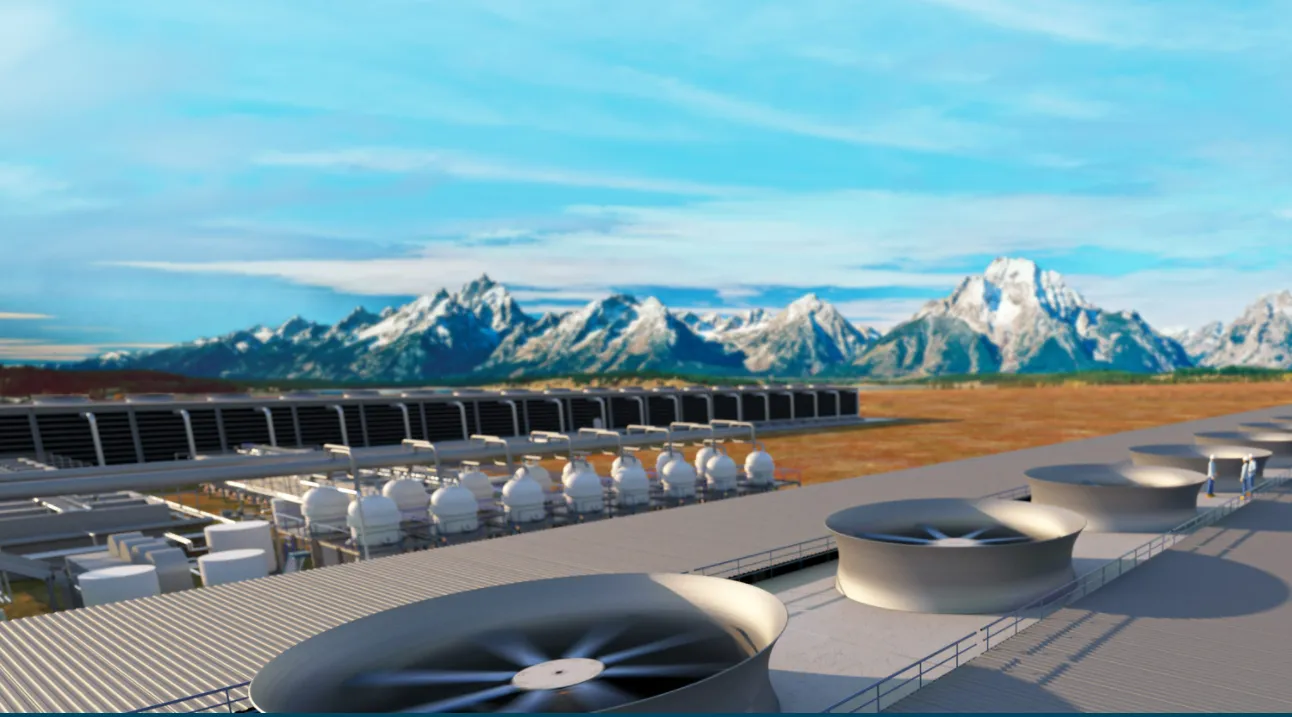

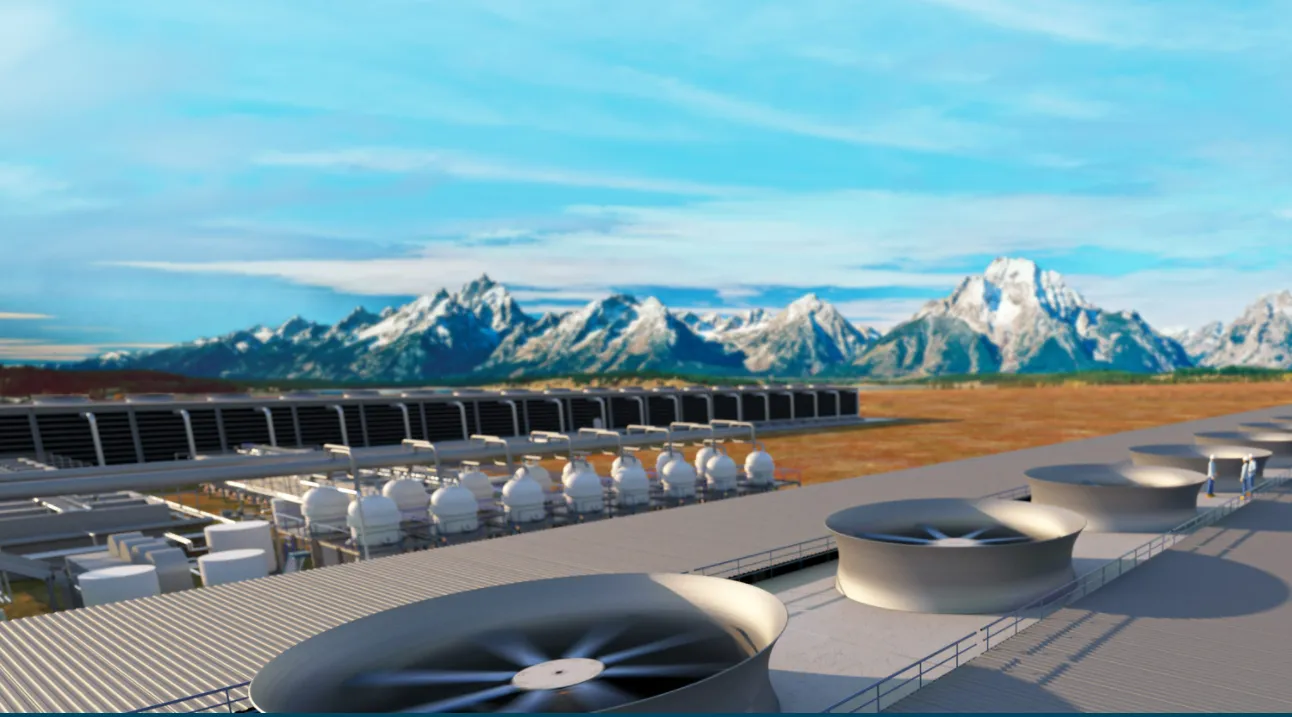

Orca, the world’s largest direct air capture plant constructed by Swiss company Climeworks and Icelandic company, Carbfix, started working in Iceland in August 2021. Climeworks will capture 4,000 tonnes of CO₂ a year, roughly equal to annual emissions of about 250 US residents or 870 western cars and Carbfix will pump the CO

2 deep into the ground, turning it into stone forever. Climeworks’ goal is to capture 1 percent of annual global CO₂ emissions, more than 300 million tonnes (mt) by 2025. Of the 16 installations, Climeworks has built across Europe, Orca is the only one that permanently disposes of the CO₂ rather than recycling it. Fifteen direct air capture plants are currently operational in Europe, the United States, and Canada. Most of these plants are small and sell the captured CO

2 for use such as for carbonating drinks. However, the first large-scale direct air capture plant is now being developed in the United States by a Carbon Engineering and Occidental Petroleum partnership. The plant will capture up to 1 mt CO

2 each year for use in enhanced oil recovery and could become operational as early as 2023.

Economics

Orca cost US $10-15 million to build, including construction, site development and storage. Climeworks is backed by a group of private investors, as well as Swiss bank, Zuercher Kantonal bank. It also has debt financing commitments from Microsoft Corp.’s climate innovation fund. The main challenge for the plant is the cost of its service. While still unprofitable, the bulk of Climeworks’ revenue comes from corporate customers including Microsoft, Stripe, Shopify, and Swiss Re. In addition, 8,000 private customers wanting to purchase carbon offsets have also signed up paying as much US $ 1,200/tonne of CO₂. For bulk purchases, such as those made by Bill Gates, the cost is closer to US $ 600/tonne.

Climeworks aims to get that cost down to US $200-300/tonne by 2030, and to US $100-200/tonne by 2035, when its operations are at full scale. The price of carbon at EU ETS (European Union Emission Trading System) is at around 60 euro/tonne (US $ 70/tonne) and it is expected to touch US $100/tonne soon. This suggests that Climeworks’s future price may become competitive for carbon offsets in the future.

The main challenge for the plant is the cost of its service. While still unprofitable, the bulk of Climeworks’ revenue comes from corporate customers including Microsoft, Stripe, Shopify, and Swiss Re.

This ambitious up-scaling of DACCS will require appropriate regulatory and policy intervention. Policy instruments and financial incentives supporting negative emission technologies are almost absent at a global scale, but the USA has initiated tax credit support for carbon capture technologies. A plant of Orca’s size is eligible for US federal tax credits equal to about US $ 35/tonne of CO

2 (tCO

2) used in enhanced oil recovery and US $50/tCO

2 storage. It is also eligible for the California Low Carbon Fuel credit, if the CO

2 is used to produce low-carbon transportation fuels. These credits traded at around US $ 180/tCO

2 in 2019.

Issues

Given the current level of CO

2 emissions approaching 40 GtCO

2/yr (giga tonnes of CO

2 per year) and the limited success of global mitigation efforts, large-scale removal of CO

2 from the atmosphere may be unavoidable. Compared to other sequestration options, capturing CO

2 directly from the air presents several advantages. It can address distributed emissions, such as those from transport, aviation and intensive industrial sectors that account for almost 50 percent of total emissions. Modular DACCS plants will allow for rapid scaling. DACCS technologies have limited land and water footprint. Studies have found that deploying DACCS significantly reduces mitigation costs, and that it complements rather than substitutes other negative emission technologies. The key factor limiting DACCS deployment is the rate at which it can be scaled up.

Compared to other sequestration options, capturing CO2 directly from the air presents several advantages. It can address distributed emissions, such as those from transport, aviation and intensive industrial sectors that account for almost 50 percent of total emissions.

According to recent modelling studies, DACCS scale-up rates of 1.5 GtCO

2/yr would require considerable sorbent production and up to 300 EJ/yr (Exajoules per year) of energy input by 2100. In 2100 it is estimated that DACCS could require around 50 EJ/yr of electricity, that is more than half of today’s total production (and about 10–15 percent of the global generation projected in 2100) and 250 EJ/yr of heat, representing more than half of today’s final energy consumption globally. To avoid additional infrastructure and pipelines to meet the energy needs of DACCS plants, they need to be co-located close to industrial facilities where waste heat is recovered, but this will limit the decentralization advantage of this technology.

Models that assume that DACCS can be deployed at scale, conclude that if DACCS is not available for various reasons, it could lead to a global temperature overshoot of up to 0.8°C. The conclusion of these studies is that DACCS should be developed and deployed alongside, rather than instead of other mitigation options.

Source: Realmonte, G. et al, “An inter-model assessment of the role of direct air capture in deep mitigation pathways”, Nature Communications, Vol. 10, 2019

Source: Realmonte, G. et al, “An inter-model assessment of the role of direct air capture in deep mitigation pathways”, Nature Communications, Vol. 10, 2019

The views expressed above belong to the author(s). ORF research and analyses now available on Telegram! Click here to access our curated content — blogs, longforms and interviews.

PREV

PREV